The invention relates to high-flux, antifouling nanocomposite hollow fiber membranes made from PES, TPGS, and functionalized carbon nanotubes. These membranes offer excellent water permeability, fouling resistance, and mechanical strength. They are easy to fabricate using a scalable dry–wet spinning process and are ideal for wastewater treatment and biomedical filtration applications.

Current polymeric HFMs are limited by low flux, high fouling tendencies, and compromised separation performance upon surface modification with hydrophobic additives like vitamin E. A need exists for a membrane that retains high flux, antifouling resistance, and mechanical integrity.

- High Flux Performance: The developed membranes demonstrate excellent pure water permeability, achieving values up to 761.1 ± 34.9 mL/m²/h/mmHg.

- Superior Antifouling Property: These membranes exhibit a high flux recovery ratio (FRR) of up to 93.7 ± 3.4% after exposure to wastewater fouling, indicating strong resistance to membrane fouling.

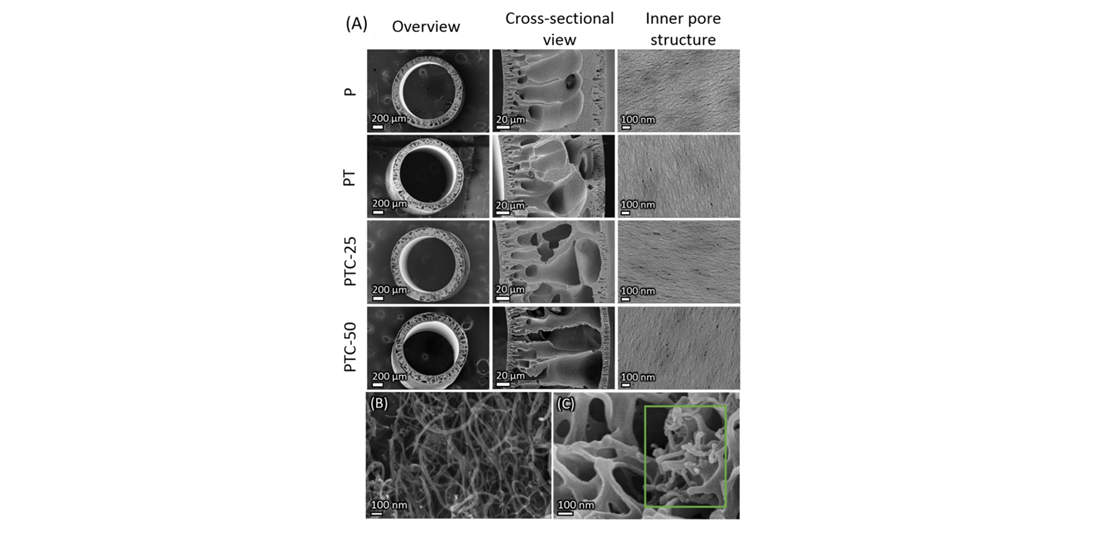

- Composite Nanostructure: The performance is enhanced by incorporating TPGS (d-α-Tocopheryl polyethylene glycol succinate) and functionalized multi-walled carbon nanotubes (MWCNTs) into the membrane matrix.

- Enhanced Biocompatibility: The use of a vitamin E derivative improves oxidative stress resistance and significantly reduces protein adsorption on the membrane surface.

- Improved Mechanical and Thermal Stability: The membranes possess high mechanical strength, with a Young’s modulus of 221.6 ± 15.7 MPa, and show improved thermal degradation resistance.

- Facile Fabrication Process: The membranes are fabricated using a simple and scalable dry-wet spinning method, making them suitable for industrial-scale production.

The developed hollow fiber membranes (HFMs), namely PTC-25 (comprising PES, TPGS, and 0.025% CNTs) and PTCf-25 (comprising PES, TPGS, and 0.025% amine/carboxyl-functionalized CNTs), were fabricated into modules and tested using BSA and synthetic wastewater. These membranes demonstrated significantly enhanced pure water permeability (PWP) and superior antifouling performance compared to unmodified counterparts.

The technology is currently ready for scale-up.

4

The technology addresses clean water access and wastewater reuse. It supports sustainable development goals (SDGs), particularly SDG 6 (Clean Water and Sanitation) and SDG 9 (Industry, Innovation, and Infrastructure). It reduces environmental impact of membrane replacement and operational downtimes.

- Wastewater Treatment: Used to filter and purify municipal and industrial wastewater efficiently

- Industrial Water Recycling: Enables reuse of process water by removing contaminants and fouling agents

- Biopharmaceuticals and Protein Separation: Ideal for separating and recovering valuable proteins with minimal fouling

- Hemodialysis and Biomedical Filtration: Offers biocompatible and high-performance membranes for medical use

- Membrane Module Manufacturing: Suitable for integration into commercial membrane filtration systems

Geography of IP

Type of IP

201923010194

380815