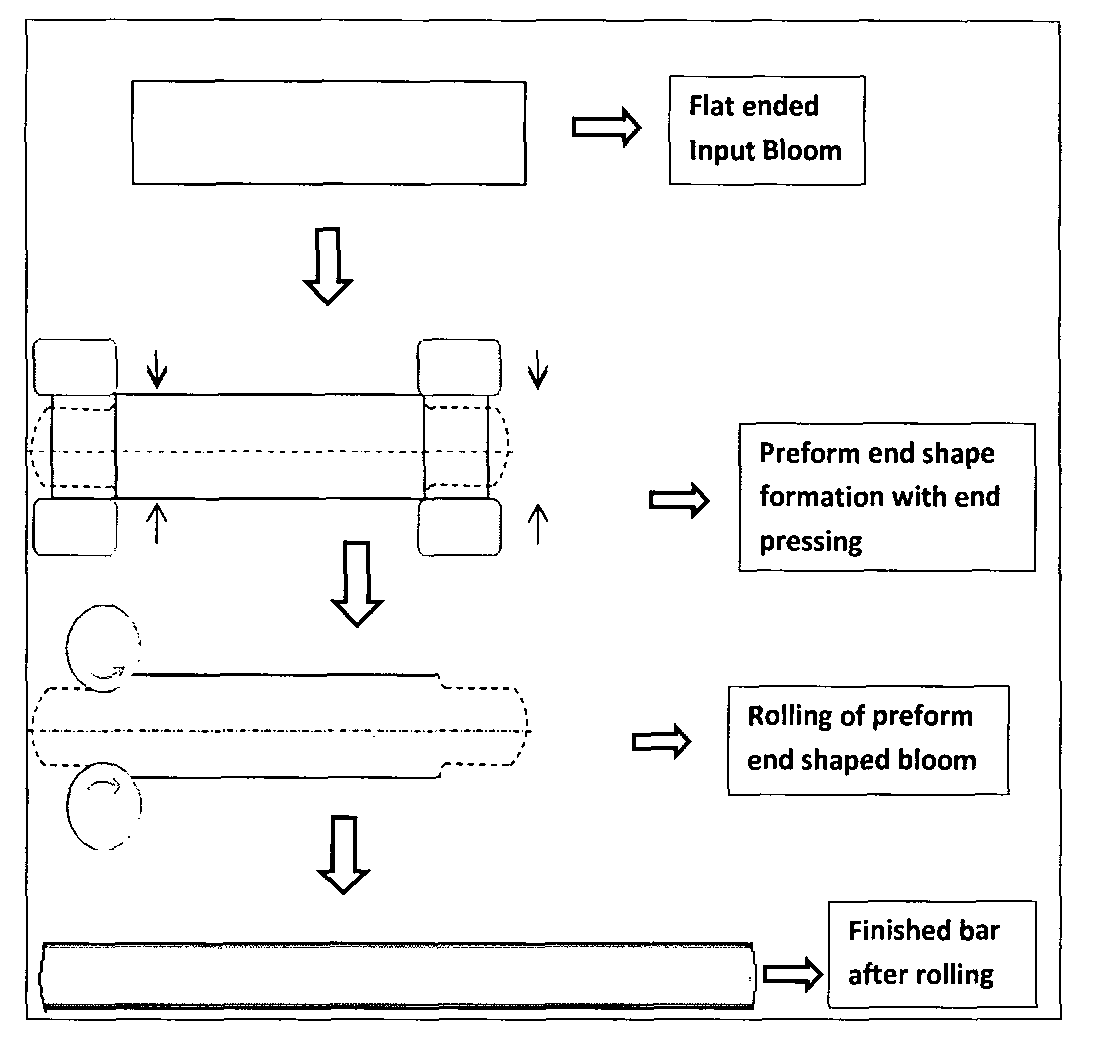

This innovation aims to reduce cropping losses in reversible multi-pass hot rolling of flat-ended blooms into bars by designing preform end shapes using finite element analysis. A three-dimensional simulation predicted defective end shapes after rolling, similar to actual observations. Reverse material tracking was applied to finite element simulations to determine approximate preform end shapes, which were then used in further simulations. The results showed a considerable reduction in cropping losses.

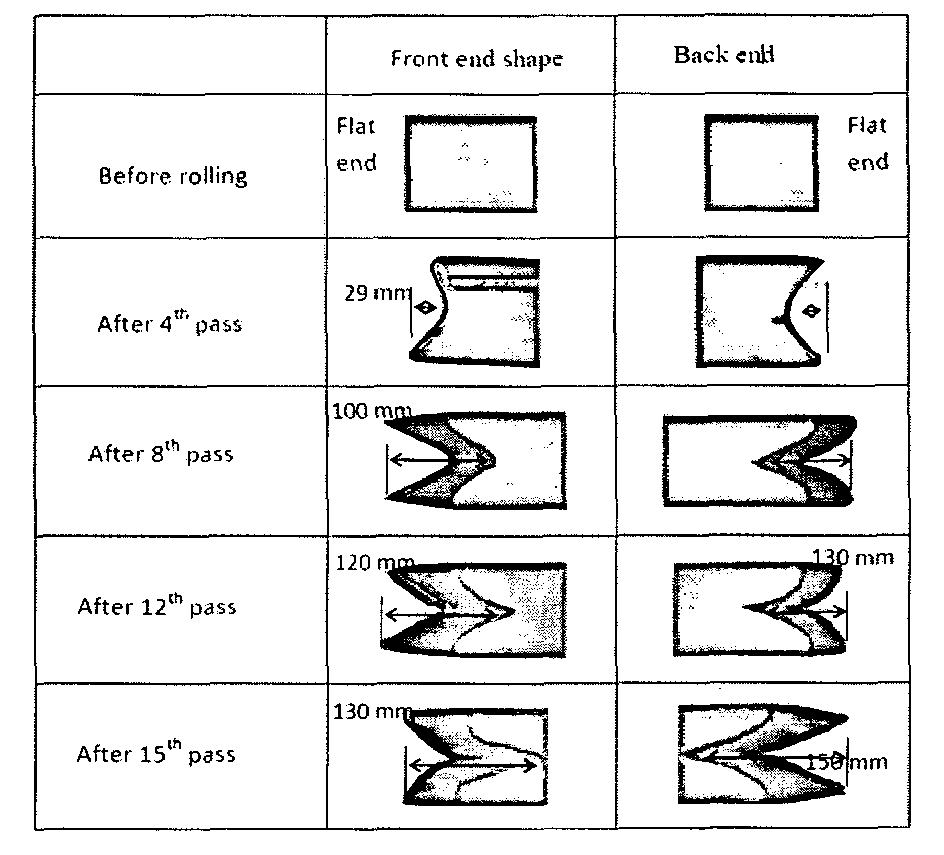

Defective front and back end shapes formed during the reversible multi-pass hot rolling process lead to significant cropping losses.

- The technology utilizes three-dimensional finite element analysis to simulate reversible multi-pass hot rolling.

- Reverse material tracking is applied to identify and design preform end shapes.

- The solution uses iterative process to refine preform shapes, leading to reduced end defects and significant reduction of cropping losses (up to 87.3%).

- There is potential for substantial material and monetary savings due to the improved yield and reduced waste in metal forming processes.

A three-dimensional model of the bloom with preform end shapes was created and simulated through 15 passes, showing reduced end defects and cropping losses.

The technology has been simulated and tested, demonstrating its effectiveness in reducing cropping losses. Further iterations and optimizations are possible for even better results.

9

This technology reduces material waste in steel manufacturing, promoting sustainability and more efficient resource use. It lowers production costs, potentially reducing consumer prices, and supports environmental conservation by minimizing the industry's footprint.

- Steel manufacturing and processing industries

- Hot rolling mills producing bars from blooms

Geography of IP

Type of IP

712/MUM/2012

446401