The invention presents a novel process for manufacturing a lightweight connecting rod using hydroforming techniques applied to metallic tubes. This approach significantly reduces the weight of internal combustion engine components, leading to improved fuel efficiency and lower emissions. The process is efficient, scalable, and environmentally friendly, making it an attractive alternative to traditional casting and forging methods.

Traditional internal combustion engines use heavy components, increasing fuel consumption and operational costs. While lightweight alternatives exist, like those from additive manufacturing, they are complex and time-consuming. A scalable, cost-effective process is needed to produce lightweight connecting rods without sacrificing strength and performance.

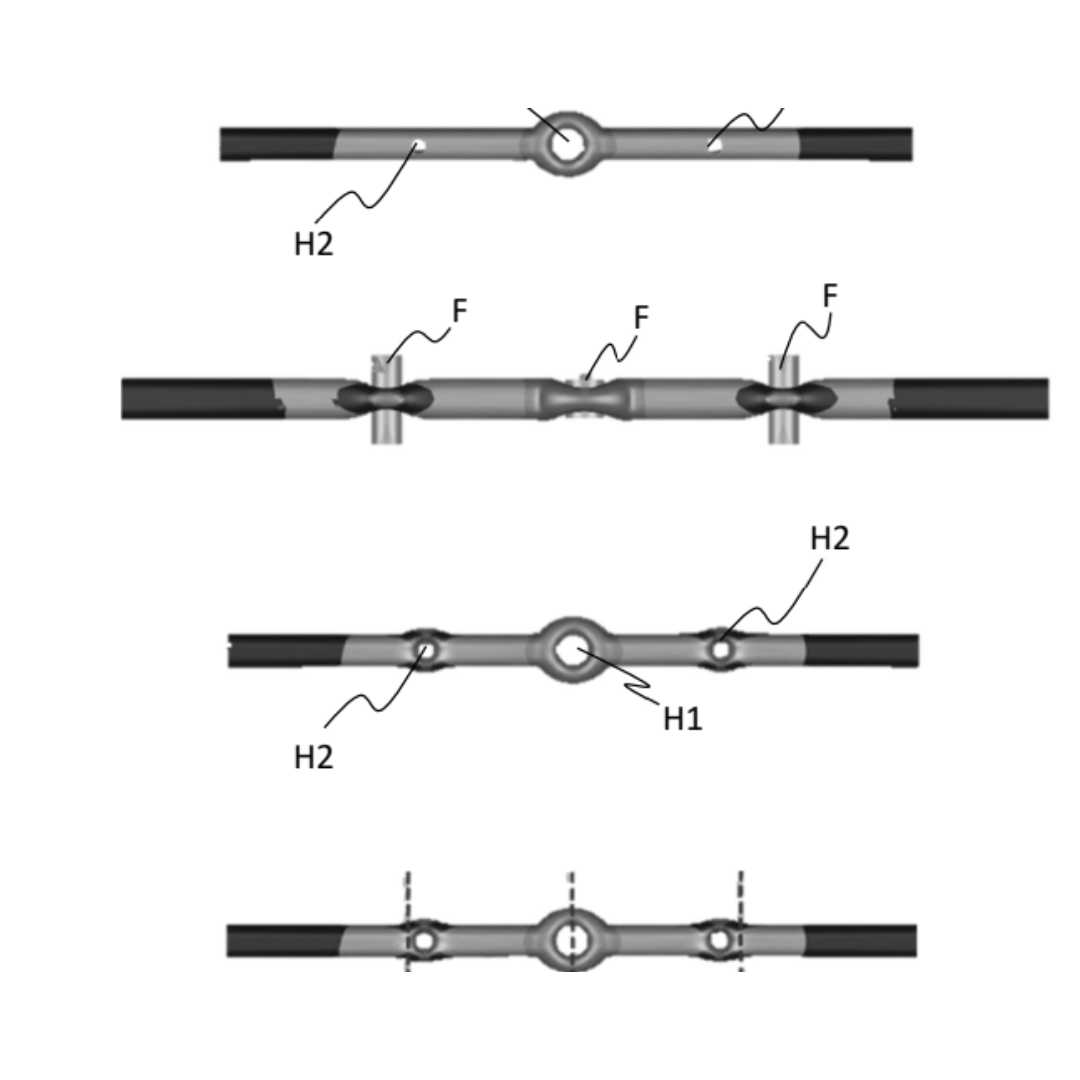

- Hydroforming process: The invention uses high-pressure working mediums to expand steel tubes within a die to form lightweight, robust connecting rods.

- Modular design: Its design allows the creation of the connecting rod's body and cap separately, which can then be assembled to form the complete rod.

- Significant weight reduction: The hydroformed connecting rod is lighter than traditionally manufactured rods, enhancing vehicle fuel efficiency.

- Cost-efficiency: It utilizes steel tubes and hydroforming, which is more economical than additive manufacturing or forging, especially on a large scale.

- Eco-friendly manufacturing: Compared to traditional methods, the hydroforming process uses less energy and generates fewer emissions.

- High performance: The resulting connecting rod maintains the necessary strength and durability for high-performance applications despite its reduced weight.

NA

The process has been thoroughly tested and validated, demonstrating its feasibility and effectiveness.

3

The technology can significantly improve vehicle fuel efficiency, leading to reduced fuel consumption and lower greenhouse gas emissions. It supports global efforts to combat climate change by promoting the development of more sustainable transportation solutions.

- Automotive industry: Ideal for internal combustion engines to lower vehicle weight and improve fuel efficiency

- Manufacturing and production: Can be applied to any sector requiring lightweight, strong connecting rods or similar components

Geography of IP

Type of IP

202021009139

523445