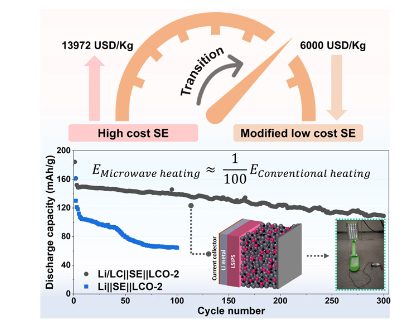

This invention outlines an ultrafast synthesis route for superionic sulfide solid electrolytes using microwave heating. This method significantly reduces the synthesis time and cost, making it a viable alternative to traditional heating methods for producing lithium silicon phosphorus sulfide (LSiPS) solid electrolytes for all-solid-state lithium batteries.

Current lithium-ion batteries with liquid electrolytes suffer from safety hazards, including low thermal stability and flammability. Traditional synthesis methods for solid electrolytes are time-consuming and costly, hindering their commercial application in advanced battery technologies.

- Ultrafast synthesis in just 30 minutes, reduces time by 16-144 times as compared to conventional methods.

- It is a cost-effective method as it eliminates the need for expensive vacuum sealing and argon gas purging, simplifying the process.

- The high-performance electrolyte delivers a high ionic conductivity (2.42 mS/cm) suitable for commercial applications.

- High fraction (~89%) of the high-conducting tetragonal phase in the synthesized product.

- The simplified process makes the synthesis more accessible for large-scale production.

NA

The technology has been successfully demonstrated with the synthesis of LSiPS solid electrolytes, showcasing significant improvements in synthesis time and ionic conductivity.

4

This technology promises safer and more efficient batteries, contributing to the advancement of electric vehicles and portable electronics, thereby reducing reliance on fossil fuels and enhancing energy security.

- Energy Storage: Enhancement of all-solid-state lithium batteries for electric vehicles (EVs), portable electronic devices, and grid storage

- Advanced Battery Technology: Potential use in next-generation batteries with higher energy densities and improved safety profiles

Geography of IP

Type of IP

202321010738

489082