The invention proposes an electromicrofluidic device for generating a biocarrier in the presence of an electric field. The device features a capillary channel with an internal surface. A first liquid inlet allows a first liquid to enter the capillary channel and acts as a liquid electrode, while a second inlet allows a second liquid to enter the capillary channel. An oil inlet is positioned adjacent to the second inlet to introduce oil into the capillary channel. The first conductive region, which includes a hollow needle connected to the first liquid inlet, serves as the liquid electrode. The second conductive region comprises a hollow cylindrical outlet and acts as a counter electrode to the liquid electrode. An electric field is applied between the conductive regions, enabling the flow of charge in a solution of the first and second liquids within the capillary channel, thereby generating the biocarrier.

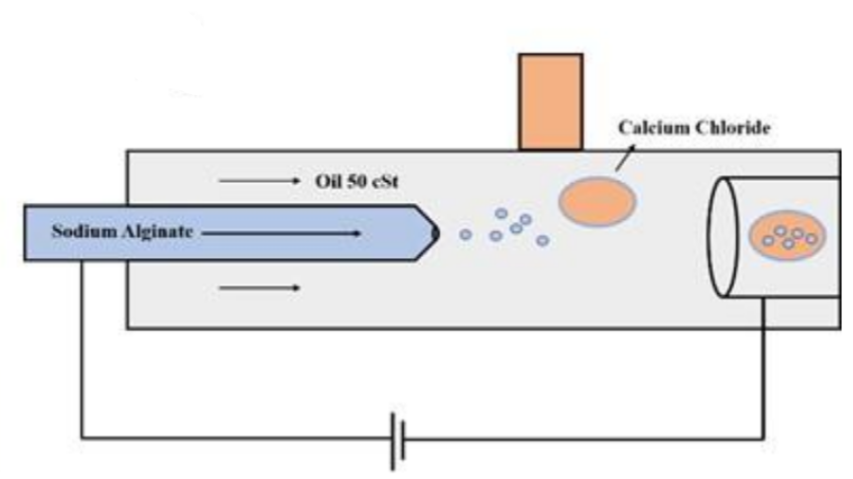

Figure (1) Image showing the 3D microfluidic device; (2) Schematic of the microgel generation mechanism inside the microfluidic device, depicting the alginate-cell droplet generation through coflow (in the presence of electric fields), calcium chloride plug formation from T-junction, the subsequent coalescence to achieve chemical gelation

One of the techniques for production of biocarriers is the microfluidic technique. It has various disadvantages in the form of reliability, operating time, and operating environment, cost or the like. The main technical drawback the polydispersity, less control on the process parameters, application of electric field and reusability.

- The device can be easily fabricated without the need for a clean room or sophisticated instruments, making it economically feasible.

- It is capable of generating microfibers and nanofibers by operating in electrospinning mode.

- It achieves reduced sizes of biocarriers.

- It utilizes a metallic electrode as the main outlet, preventing blockage and clogging.

- It is easily removable, facilitating the cleaning of the electromicrofluidic device and enhancing its reusability for multiple experiments.

- Easy modifications to the design in terms of adding additional channels, etc. can be made.

The PDMS and glass capillary were utilized to fabricate a 3-dimensional hybrid microfluidic device. A rectangular Teflon frame, measuring 250 mm in width and 450 mm in length, with a 2 mm hole on both sides of the base for inserting the square capillary, was used as a mold. The frame was then adhered to a glass petri dish, resulting in a square channel of 1.4 mm in the PDMS slab. A channel of 0.5 cm was created from the top and 2 cm from the side using a 16G needle for the oil inlet. Similarly, another side channel hole was created using a 16G needle for the calcium chloride inlet. The PDMS slab was bonded to a glass slide using a plasma bonding machine, and a glass capillary with a tip diameter of 60 mm was axially aligned inside the square channel for the generation of alginate droplets. A hollow copper metallic cylinder with an outer diameter of 1.4 mm was inserted into the other end of the PDMS square channel, which was then connected to Teflon tubing.

The invention has a proof of concept developed. An experimental setup and a working principle of the device has been proposed.

3

The invention has applications in major areas such as drug delivery, therapeutic applications, tissue engineering, which can be used to battle diseases and promote better health of the public.

This device can be commercially utilized for generating microparticles, emulsions, and microcapsules in the food, biomedical, and chemical industries for various applications. The current method of droplet merging in the presence of an electric field can be employed to produce microparticles and microcapsules of reduced size. The design is easily modifiable to suit specific applications. The proposed method and design can also couple active droplet generation methods with on-chip gelation for the effective production of 3D biomaterials.

Geography of IP

Type of IP

202121035979

538730