The present invention pertains to ice-phobic coatings that are both anti-icing and de-icing, maintaining their efficacy across multiple freezing cycles. Specifically, the invention involves a coating composition that includes crosslinked soft particles, which enable the slow release of small molecule freezing point depressants. Additionally, it features a high-volume fraction of these hydrophilic soft particles dispersed within a hydrophobic crosslinkable medium. These ice-phobic coatings are designed to be durable, cost-effective, and capable of enduring repeated frosting cycles while providing effective anti-icing and de-icing performance.

Past inventions of coatings to be used for anti-icing and de-icing have been known to suffer from loss of effectiveness and are not mechanically robust. Developing coatings that are effective for both anti-icing and de-icing, while also being durable (mechanically and through multiple frosting cycles) and cost-effective, remains a highly challenging and essential problem.

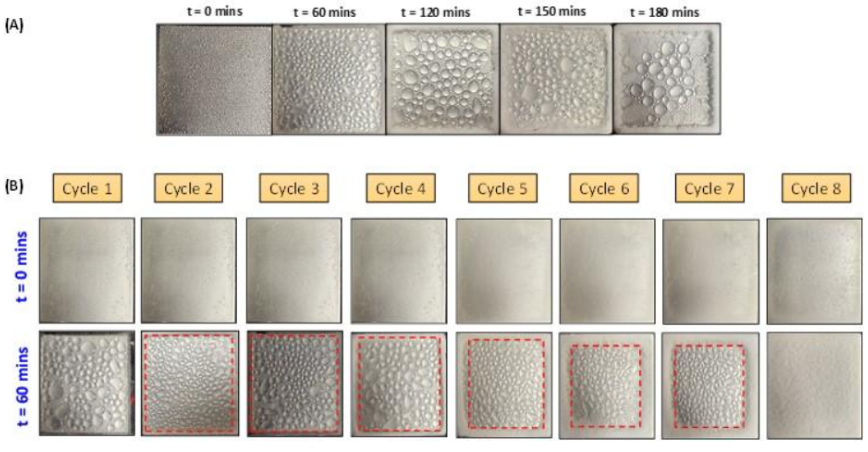

- Performance Retention: This technology has a robust ability to retain performance over many cycles of frosting.

- Frost Delay: It is capable of significantly delaying frost formation on a test aluminum substrate.

- Force Reduction: It can decrease the force required to shear off the ice that is formed on the surface.

- Slow Release: It uses crosslinked soft particles that allow slow release of the small molecule freezing point depressant.

- Modulus Reduction: Blended coating comprises a majority included phase that slowly releases a freezing point depressant and decreases the modulus.

- Mechanical Stability: Minority matrix phase provides mechanical stability to the coating.

- Anti-Icing Performance: It provides excellent anti-icing performance even in extremely harsh conditions.

The prepared coating consists of two distinct phases. Phase 1 is a rigid elastomeric material, while Phase 2 is a soft gel that gradually releases a freezing point depressant. To prepare the gel, 2.5 grams of gelatin are dissolved in 30 milliliters of a DMSO-water (90:10) solution with slight heating and vigorous stirring. After dissolution, 100 microliters of the glutaraldehyde (GTA) crosslinker is added to the mixture, which is then immediately transferred to a petri dish and cured at room temperature. This gel serves as the Phase 2 material for the ice-phobic coating. For the Phase 1 matrix, a predetermined weight of RTV-1 silicone is added to 15 milliliters of xylene solution and stirred continuously until fully dissolved. This solution forms the rigid elastomeric component of the ice-phobic coating.

The invention is at the stage of Demonstration and/or validation in lab environment. The coating has been tested in labs and has shown better performance than other known coatings in the case of both anti-icing and de-icing.

4

Preventing ice formation (anti-icing) and facilitating ice removal (de-icing) on various surfaces is of significant practical importance. For instance, ice formation on aircraft necessitates time-consuming and expensive de-icing procedures before operation. Similarly, ice accumulation on power lines in cold regions can lead to power outages and requires de-icing. Due to the widespread impact of these issues, there is an ongoing interest in developing cost-effective and durable anti-icing and de-icing technologies.

- Airplane industry

- Electric power industry

- Military and Defense industry

- Marine industry

- Construction industry

- Transportation industry

Geography of IP

Type of IP

202321039556

517107