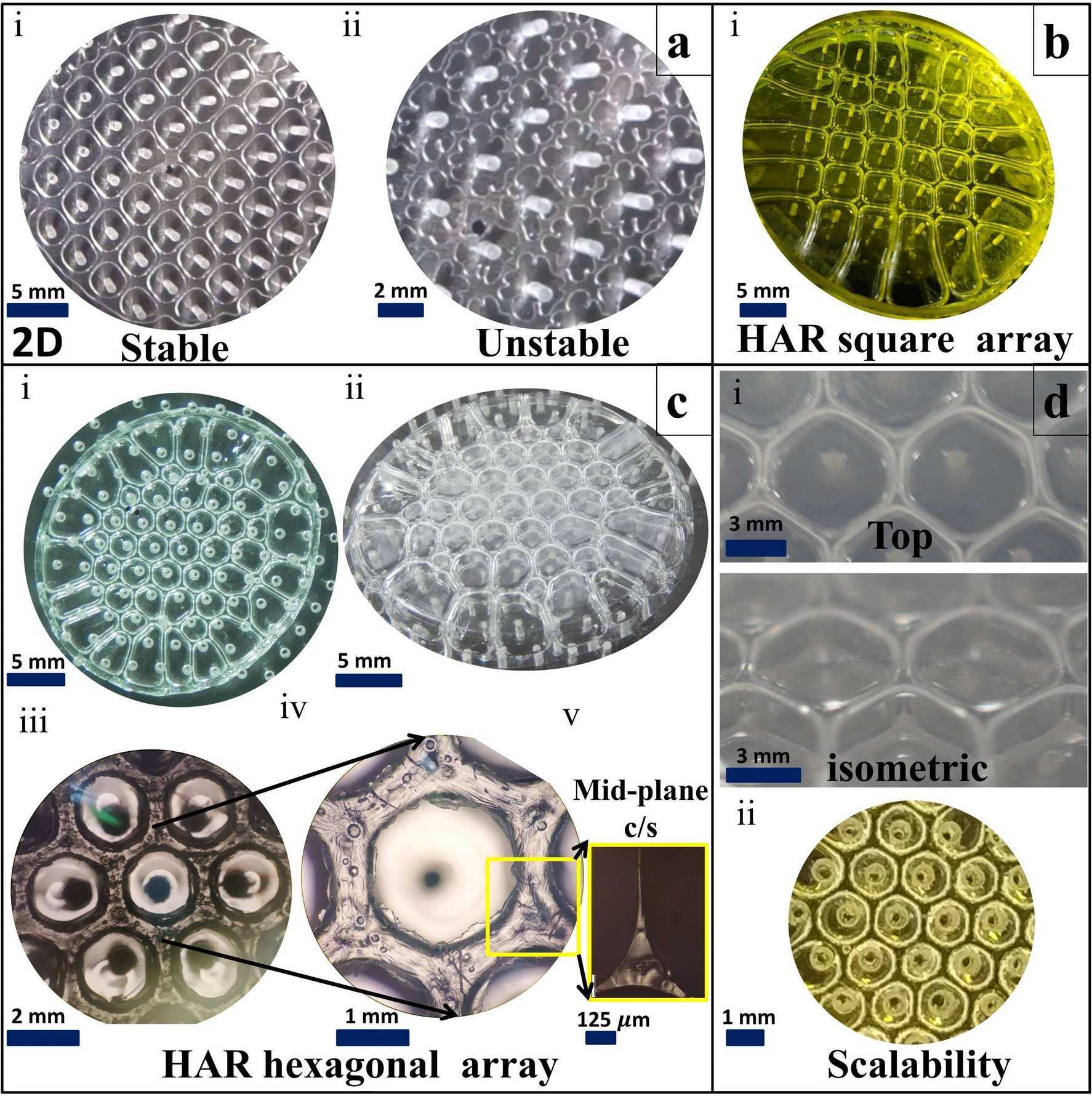

The method and apparatus enable the creation of high aspect ratio structures, which are tall and thin 3D shapes. The process involves depositing a special viscoelastic fluid (a mixture of a volatile solvent and a polymer) on a bottom plate, compressing it with a top plate, and then slowly separating the plates. This separation stretches the fluid and allows a low-viscous fluid to penetrate through small holes in the plates. As the solvent evaporates, the desired tall, thin structures are formed. This technique can be applied to various high-tech applications and allows for precise and complex 3D shapes.

Existing manufacturing technologies with bottom-up or top-down approaches face challenges in balancing cost-effectiveness, time-efficiency and scalability, especially when it comes to fabrication of nature inspired multi-scale geometries. Available microfabrication techniques involve multiple process requiring expensive equipment and even then are not scalable. This invention reveals lithography-less technology that offers simple yet elegant, robust, frugal, time efficient and controlled approach to fabricate 3D fractal-like and array structures with high aspect ratio walls ex. nature-inspired honeycomb. The process involves fluid reorganization of the evaporative polymer solution between two strategically modified plates by simply squeezing and lifting. This work establishes a solid foundation with valuable insights for rapid manufacturing of devices useful for biomedical domain and it may further find use towards metamaterial development.

- Cost-effective and Time-efficient: The lithography-less process reduces both the cost and time compared to conventional methods.

- Spontaneous Fabrication: This technology achieves complex 3D geometries through a simple two-step process of fluid squeezing and separation.

- Scalable for Multi-scale Fabrication: It is suitable for creating any array structure with high aspect ratio (HAR) walls across various scales without increasing costs.

- Versatile Applications: It is capable of producing diverse patterns, such as honeycomb structures, square lattices, and biomimetic designs, ideal for applications in cell research, drug screening, and tissue engineering.

- Metamaterial Potential: It allows for the creation of 3D metamaterials by stacking multiple high aspect ratio hexagonal wells.

- Innovative Fluid Shaping Method: It involves fluid reorganization of the evaporative polymer solution between two strategically modified plates by simply squeezing and lifting.

The prototype produces high aspect ratio 3D multiscale structures with dimensions ranging from 10 micrometers to several millimeters, accurately controlling fluid-fluid interface instability.

Several systems and prototypes for multiple scales have been developed based on this technology and tested in the laboratory successfully.

4

The proposed technology has potential for biomimicry, making it valuable for lab-on-a-chip devices (e.g. spheroid formation in wells) and phantom making industries. Additionally, this technology may enable the creation of 3D metamaterials by stacking multiple high aspect ratio structures.

- Biomedical Devices: Facilitates the creation of intricate structures for biomedical devices like microfluidic chips.

- Regenerative Medicine: Enables the fabrication of complex tissue scaffolds and microenvironments for tissue engineering.

- Metamaterials: Facilitates large scale fabrication of metamaterials for various applications

Geography of IP

Type of IP

202021034604

479374