Touch screens have become the ubiquitous interface for controlling contemporary electronic devices and incorporated into almost all the new technologies starting from smart phones, computers, flat panel televisions to personal gadgets and household appliances. One of the key components of touch screen is a transparent conducting electrode (TCE) which is optically transparent and electronically conductive. TCEs are also the backbone of optoelectronic devices eg. organic light emitting devices (OLEDs), photovoltaics (PVs), liquid crystal devices (LCDs) electro chromical devices (ECDs) etc. The most abundantly and conventionally used TCE is indium tin oxide (ITO) which has been the market leader in this field for decades. The high cost of ITO due to scarcity of indium on earth (160 ppb by weight) and tedious vacuum processing based recovery involved, there is a demand for alternative materials.Moreover, the incompetence of ITO coating on flexible substrates (electronics) is an additional disadvantage. Organic conducting polymers are the potential alternative to ITO and PEDOT:PSS [poly(3,4-ethylenedioxythiophene) polystyrene sulfonate] is one such conducting and transparent polymer. This can be printed using conventional techniques and hence suitable for large area flexible optoelectronic applications.

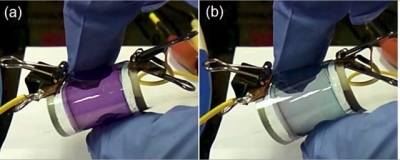

In this direction, we have developed a process wherein both the conductivity as well as transparency of PEDOT can be improved making it an ideal candidate to replace ITO for flexible transparent conducting coatings. These TCEs were used for constructing organic ECDs on flexible substrates using solution processable methods. We obtained the device performance similar to that of ITO based ECDs. These devices were tested for multiple electrochemical and mechanical cycling. The added advantage of these devices is their bendability where the performance of ECDs does not degrade on repeated bending tests ( >1000 bending cycles).

Prof. A Kumar