The proposed technology for compression ignition internal combustion engine capable of operating on both diesel and gasoline fuels addresses the dual challenges of high NOx and soot emissions from diesel engines and low thermal efficiency from gasoline engines. This is achieved by integrating a control system that enables non-simultaneous operation in diesel Direct Injection (DI) mode and gasoline Homogeneous Charge Compression Ignition (HCCI) mode. This system ensures seamless transitions between modes without the need for simultaneous fuel injection, thereby simplifying engine control mechanisms and improving fuel efficiency.

The innovation stands out by requiring minimal modifications to existing engine designs, making it a cost-effective and practical solution for a variety of applications, including automotive, power generation, agricultural machinery, and industrial machinery.

The prototype demonstrates stable performance across different load conditions, significantly reducing harmful emissions and contributing to cleaner air and better public health. This technology offers a viable pathway to achieving higher fuel efficiencies and lower operational costs, benefiting both the environment and the economy.

Traditional Compression Ignition (CI) diesel engines offer high thermal efficiency but result in increased NOx and soot emissions. Conversely, Spark Ignition (SI) gasoline engines produce acceptable emission levels but have lower thermal efficiency. Homogeneous Charge Compression Ignition (HCCI) and Premixed Charge Compression Ignition (PCCI) methods attempt to combine the advantages of both CI and SI engines but have previously faced significant challenges, particularly in maintaining stable combustion at varying loads.

- Control System: This innovation contains a control system that enables seamless transition between a stationary CI engine in the diesel-DI mode and the gasoline-HCCI mode.

- Non-Simultaneous Operation: It operates independently in each mode, reducing complexity and improving efficiency.

- Ease of Integration: This technology requires minimal modifications to the engine subsystems, and no modifications to the engine itself, making it cost-effective and practical.

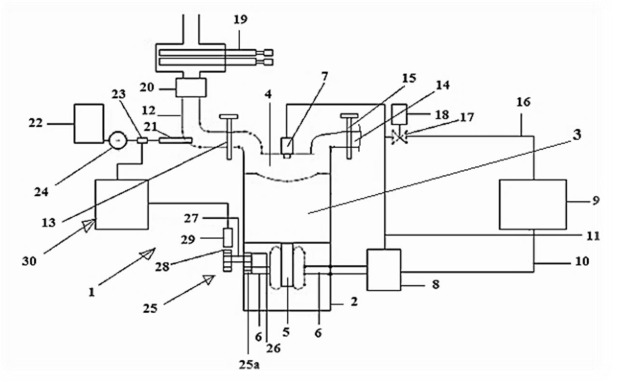

A modified stationary single-cylinder CI engine operates non-simultaneously on diesel and gasoline. It features separate fuel delivery subsystems and a control circuit that manages transitions between gasoline-HCCI and diesel-DI modes, demonstrating stable performance across different load conditions.

The technology has been demonstrated and validated in lab environment.

4

This technology aims to reduce the environmental footprint of diesel engines by lowering NOx and soot emissions while maintaining high thermal efficiency. This can contribute to cleaner air and reduced greenhouse gas emissions, addressing both environmental and public health concerns.

- Automotive: Enhancing diesel engine efficiency and emission profiles

- Stationary Engines: Improving performance in power generation and industrial applications

- Agriculture: Reducing emissions from engines used in agricultural machinery

- Commercial Vehicles: Meeting stringent emission norms without compromising performance

Geography of IP

Type of IP

3787/MUM/2014

398756