The invention is shown to achieve uniform deposition of particulate types on carbon fiber fabric. This approach enhances the fabrication of vacuum assisted resin transfer molding (VARTM) laminates with improved mechanical properties.The method enables rapid and uniform deposition of functionalized graphene platelets onto carbon fiber fabric. It was observed that uniform deposition of particulates on the fabric facilitates effective resin impregnation during composite manufacturing and increases the interphase thickness of fibers, thereby enhancing the mechanical properties of the composites.

Carbon fiber reinforced polymers (CFRP) often experience failures at the interface between the fibers and epoxy resin under mechanical loads due to weak interfacial bond strength. While electrophoretic deposition (EPD) is effective in enhancing this bond strength, it suffers from challenges such as poor dispersibility and lengthy deposition times, making it unsuitable for continuous production of high-performance carbon fiber fabrics.

- Carbon fiber fabric obtained has improved tensile and flexural properties

- Carbon fiber fabric is further used in composite fabrication to improve the interfacial properties

- Carboxyl functionalized graphene (G-COOH) platelets are dispersed in a solution, prepared by adding Mg (NO3)2 in DI water.

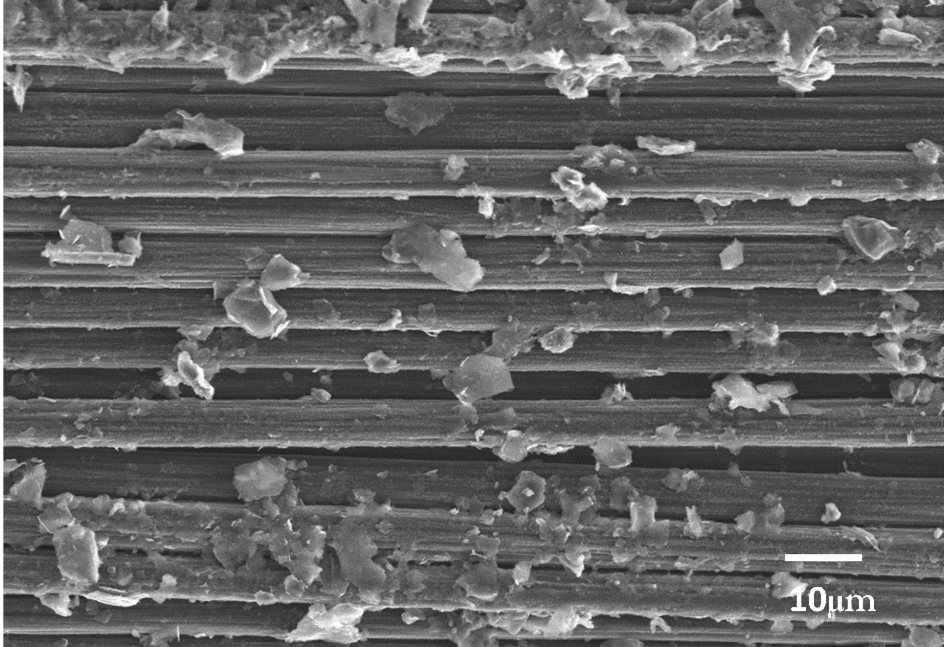

- It has individually deposited particles with no agglomerations.

- It has achieved uniform deposition of G-COOH particles on carbon fiber fabric.

- It helps to reduce the time of deposition, and the weight of G-COOH platelets.

Before deposition, pristine carbon fiber (CF) fabric was cut into 150 mm × 150 mm pieces, and copper tape was wrapped around all four edges. A dispersion solution was then prepared. The CF fabric was immersed into the suspension in the middle slot of the container and connected to the cathode (-) working electrode. Two stainless steel plates, each measuring 150 mm × 150 mm with a thickness of 0.6-1.4 mm, were placed on either side of the working electrode and connected to the anode (+) counter electrode. The gap distance between the working electrode and the counter electrodes was set between 0.6-1.4 cm. The optimized process parameters for achieving uniform particulate deposition involved applying a constant direct current voltage of 9-21 V and a deposition time of 12-28 minutes.

The invention has a proof of system and is ready for deployment. Carbon fiber fabrics underwent sonication-assisted EPD with uniformity of deposition and were compared with pristine carbon fiber specimen. They showed improved tensile and flexural properties over the specimen.

9

This technology can be used in various engineering sectors such as robotics, industrial equipment and machinery components.

The invention gives carbon fiber fabrics with improved tensile and flexural properties. Carbon fiber fabrics have applications in various industries such as aerospace, marine, automobile, energy, sports and so on.

Geography of IP

Type of IP

202321028906

507587