Methods and systems for Discontinuity Detection in Pipelines

It is an innovative approach to managing pipelines, explicitly focusing on detecting discontinuities such as leaks or bursts. This technology is crucial because pipeline failures can cause severe environmental damage and financial loss and pose risks to human life. The method features a strip associated with the pipeline, which can be placed on the surface or embedded within the pipeline. The core functionality is based on detecting variations in capacitance, which indicates changes in the pipeline's length or circumference due to discontinuities. The technology is independent of the type of fluid flowing within and temperature variations (under deformation limits). Further, the system demonstrates high sensitivity, enabling the detection of small discontinuities, and can be implemented cost-effectively.

Existing pipeline discontinuity detection systems face significant challenges in terms of accuracy, cost, and applicability. Current hardware-based methods, including in-pipe sensors and out-of-pipe devices like acoustic emissions or ultrasound, suffer from limitations such as false alarms, reduced resolution due to pipe non-uniformities, interference, and high installation costs. While optical cable-based methods offer higher resolution, they are expensive, incompatible with many existing pipelines, and significantly affected by reflections and temperature change in the surroundings of the pipelines. Novel metallic strips are fixed to the outer surface of the pipe are used to predict the length at which the discontinuity is witnessed. These strips are inscribed to the surface of the pipeline. This solution is can easily be implemented to the existing pipeline

- Accuracy: High-resolution detection of leaks and bursts due to the precise measurement of capacitance changes.

- Cost-Effectiveness: Lower installation and monitoring costs compared to traditional optical cable systems.

- Flexibility: Can be applied to various pipeline materials and sizes, and can be mounted on the surface or embedded during pipeline manufacturing.

- Real-Time Monitoring: Provides continuous or periodic data on pipeline integrity, allowing for immediate response to detected discontinuities.

- Non-Dependency on Pipeline Material or Fluid Type: The detection system is not influenced by the type of fluid or gas in the pipeline, nor by the temperature under normal conditions.

- Low Power Consumption: The system’s minimalist design and reliance on capacitance measurement translate to minimal power requirements, making it suitable for remote or long-term deployments.

- This can be incorporated to any existing pipeline carrying oil, natural gas or water.

- The technology is very reliable with obtained accuracy of ±0.04 m.

- The observed uncertainty in the measurement of the self-capacitance is ±3.9%.

- Repair can be done by adding an additional metallic strip as a lap joint.

- Negligible operating power required.

- The capital cost is very minimal. It is only 20% of that of the existing solution.

- Continuous damage monitoring of the considered pipeline (Metallic and non-metallic) can be obtained.

- No error or interference due to Cathodic Protection.

- Can work with both insulated and uninsulated pipes.

- Possess higher operational range.

- Change of temperature and pressure has no effect on the result.

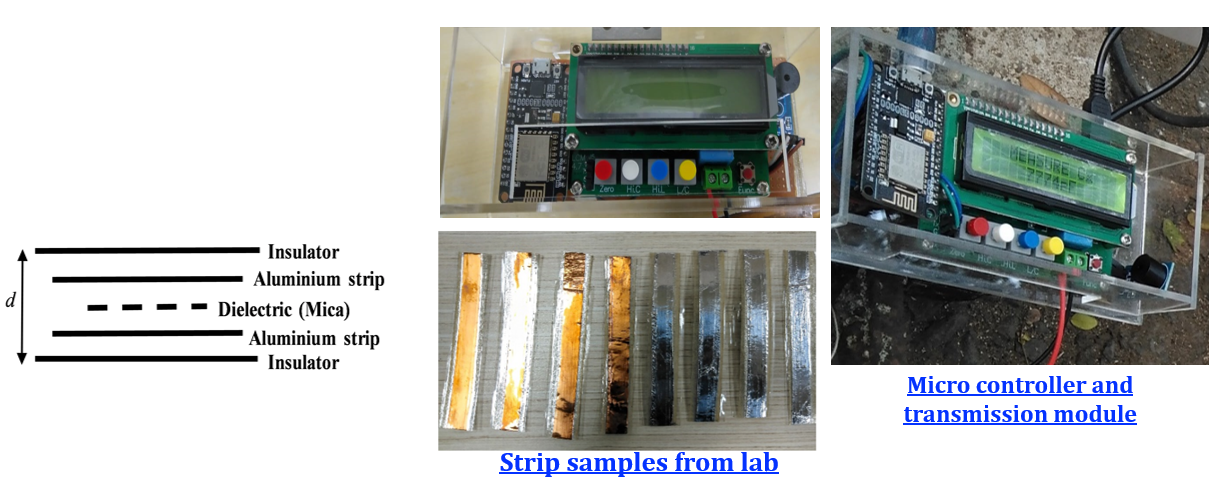

The method consists of a strip with multiple layers, comprising two metallic layers (aluminum or copper), a dielectric layer (like mica) sandwiched between them, and outer insulation layers (polymer of Vinyl). This strip, attached externally or molded into the pipeline, forms a capacitor. The prototype measures the self-capacitance across the strip using a capacitance measurement device. It correlates changes in capacitance to discontinuities in the pipeline, as capacitance is directly proportional to the strip’s length. A decrease in capacitance indicates a reduction in the strip’s effective length, signifying a potential discontinuity. The prototype is tested with air, water, and oil flow at varying velocities and temperatures. Results demonstrate the ability to detect discontinuities, with a resolution of ±0.04 m achievable using a 0.001m wide strip. The system exhibits a 7.7% uncertainty in capacitance measurement. Notably, fluid type and flow velocity minimally impact capacitance. However, temperature variations, while resulting in a uniform capacitance increase, necessitate system calibration for accurate discontinuity detection.

It offers a cost-effective and reliable method for detecting discontinuities in pipelines. Pipeline leaks and bursts pose serious risks, including environmental damage, economic losses, and threats to human life. The low cost and minimal power consumption of the system make it particularly suitable for widespread deployment, potentially enhancing the safety and sustainability of critical infrastructure for fluid and gas transportation. This can lead to reduced environmental incidents and contribute to a more secure and efficient energy sector.

The primary application domain for this pipeline discontinuity detection technology is the oil and gas industry. The system could be adapted for use in water distribution networks, chemical processing plants, and any sector reliant on pipelines for transporting fluids.