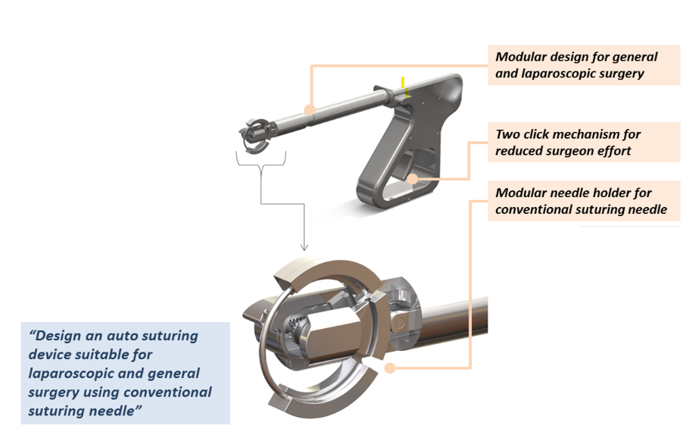

An Automated Needle Holder And Suturing Device

An automated needle holder and suturing device simplifies and expedites surgical suturing procedures. It consists of an arcuate jaw member with a slotted guide for precise needle movement, a collapsible jaw assembly for flexibility in suturing, and a sector element that secures and guides the needle through the stitching process. A trigger mechanism controls the movement of the needle, completing a single stitch cycle in two stages. The device ensures precise needle placement and controlled movement, minimizing tissue trauma and improving surgical efficiency.

Current suturing devices for open and laparoscopic surgery need several limitations, hindering precise and efficient tissue suturing. Existing devices often necessitate complex maneuvers to ensure accurate needle placement and struggle to maintain a secure grip, particularly in tight operating spaces or when dealing with delicate tissues. Many available solutions utilize specialized needles and sutures, limiting their versatility and compatibility with standard surgical practices. Moreover, these devices often fail to address the fundamental principles of optimal suturing, such as needle grip selection, tissue approach angle, and needle movement patterns, leading to subpar results, particularly for less experienced surgeons. This automated needle holder and suturing device simplifies these complex tasks, enhances precision and speed, and allows for consistent, accurate suturing across various surgical scenarios while remaining compatible with commonly used needles and sutures.

- Slotted guide and sector elements to ensure accurate needle movements along the intended path, enhancing precision.

- Automated needle handling and suturing reduce the physical demands on the surgeon for longer procedures with less strain.

- Collapsible jaw assembly and adjustable components enable the device to be used in various surgical situations, enhancing its applicability.

- Automated actions ensure each suture is performed with uniformity, improving overall surgical outcomes.

- Arcurated Jaw & Guided Needle: Consists of a slotted guide on the top surface, designed to align with the curvature of the surgical needle, ensuring accurate guidance and control of the needle during suturing.

- Collapsible Jaw Design: Comprises segmented jaw elements that can converge towards each other, allowing the device to adjust its diameter to suit different suturing scenarios and facilitate easier entry for minimally invasive surgery.

- Automated Needle Movement: Automates needle motion and has a unique grip and release mechanism during suturing.

- Sector Element with Pincher Mechanism: Engages with the needle at specific points to control its angular displacement, aiding in the precise execution of stitches through coordinated movements.

- Spring-Loaded Trigger Assembly: A two-step trigger (press and release) controls the needle's rotation and facilitates the automated and stepwise movement of the needle.

The device comprises an arcuate jaw member, a curved needle, a needle mover assembly, a rack and pinion assembly, a piston element, a biasing element, and a plunger. The arcuate jaw member features a slotted guide for guiding the curved needle, while the needle mover assembly engages with the needle for frictional movement. The rack and pinion assembly enables the axial and linear movement of the needle mover assembly. The piston element, triggered by a trigger assembly, facilitates linear sliding. The biasing element, coupled with the piston and rack elements, guides a plunger. The plunger, acting as a rocker arm, interacts with the biasing element's slotted profile to control needle movement. The device further includes a gear, clutch, spacer, and link mechanism for precise needle articulation. Through a series of trigger actions and spring-loaded mechanisms, the device automates the process of passing the curved needle through tissue, completing a single stitch with two trigger activations.

The automated needle holder and suturing device stands to significantly impact surgical procedures by improving their efficiency and accessibility. It can reduce surgery durations and minimizing tissue trauma. This could lead to faster patient recovery times and reduced healthcare costs. Additionally, by simplifying the suturing process, the device could make advanced surgical techniques more accessible to less experienced surgeons, particularly in underserved areas with limited access to specialized medical expertise. Furthermore, the device's ability to function in both open and laparoscopic surgeries expands its potential applications across various medical specialties, contributing to improved patient outcomes and overall healthcare quality.

The automated needle holder and suturing device is primarily designed for the medical and surgical field, aiming to assist surgeons in performing sutures with enhanced precision and efficiency. Primary application lies in minimally invasive laparoscopic surgeries, the device's core functionality – automated manipulation of a curved needle through a constrained space.