Oxidation-resistant, nickel-based superalloy promises cleaner coal-based power generation

Researchers are continuously looking for ways to make coal power generation cleaner and more efficient. Innovative experiments were conducted on a new kind of nickel alloy that showed promising resistance to oxidation in extreme temperature and pressure conditions. These findings can be instrumental in reducing the environmental impacts of using fossil fuel-based sources like coal for power generation while boosting efficiency levels in the power sector.

At present, most coal-based power plants operating in subcritical conditions (17 MPa pressure and 540 ℃ temperature) produce steam from pure water for power generation. The generated high temperature water and steam can corrode the surface of the tubes they pass through due to oxidation. This can also cause a thin film on the surface, like a coating, that can reduce the efficiency of power generation. The water in the proposed Advanced Ultra Supercritical (AUSC) plants, designed to operate at 32 MPa pressure and 710 ℃ temperature, is expected to corrode the tubes much more significantly. The challenge in increasing the efficiency, safety and reliability of such plants is to prevent corrosion to the extent possible. Researchers have been exploring various superalloys which are heat-resistant alloys of nickel, iron-nickel, and cobalt that can be used at high temperatures.

A team of researchers at the Indian Institute of Technology Bombay (IIT Bombay) have reported promising results in a steam oxidation test conducted on Ni-base superalloy 617, or Alloy 617,which is expected to transform the functionality of coal-based power plants. The tests were performed in a simulated Advanced Ultra Supercritical (AUSC) environment, specifically designed to replicate the extreme temperature and pressure conditions that exist in a coal-fired power plant.

AUSC power plants are a special type of power plants that operate at extremely high temperatures and pressures - around 710 ℃ and 32 MPa, respectively. These conditions allow the power plant to achieve thermal efficiencies of about 50% and convert more of the plant’s coal into usable electricity. Thus, it could reduce carbon dioxide emissions by approximately 30% compared to subcritical power plants. The challenge lies in developing materials that can withstand these harsh operating conditions while not deforming under extreme stress at specified higher temperatures (creep strength) and exhibit oxidation resistance.

“We were naturally excited to work on this project because any research that would help reduce carbon emissions is always welcome. Given the expertise at IIT Bombay, we were invited by the Mission Directorate, Advanced Ultra Supercritical Project, Government of India, headed by Mr.S. C. Chetal to undertake this study. It was a national project in mission mode and the Government of India wanted to go ahead with thermal power plants with higher thermal efficiency,” says Prof Raja as the motivation behind this study.

Until now, Alloy 617 has remained relatively unexplored for potential use in AUSC technology due to difficulties in creating a test loop that simulates the extreme conditions of an AUSC steam oxidation test loop. Previous studies have been limited and inconclusive, with the steam temperature and pressure conditions examined not exceeding 670 ℃ and 27 MPa, respectively and water chemistry not controlled precisely.

Researchers exposed Alloy 617 to a simulated AUSC steam test, subjected to a range of 650–710 ℃ at 31 MPa for 600 hours to simulate an environment similar to the power plant's superheater and reheater tubing.

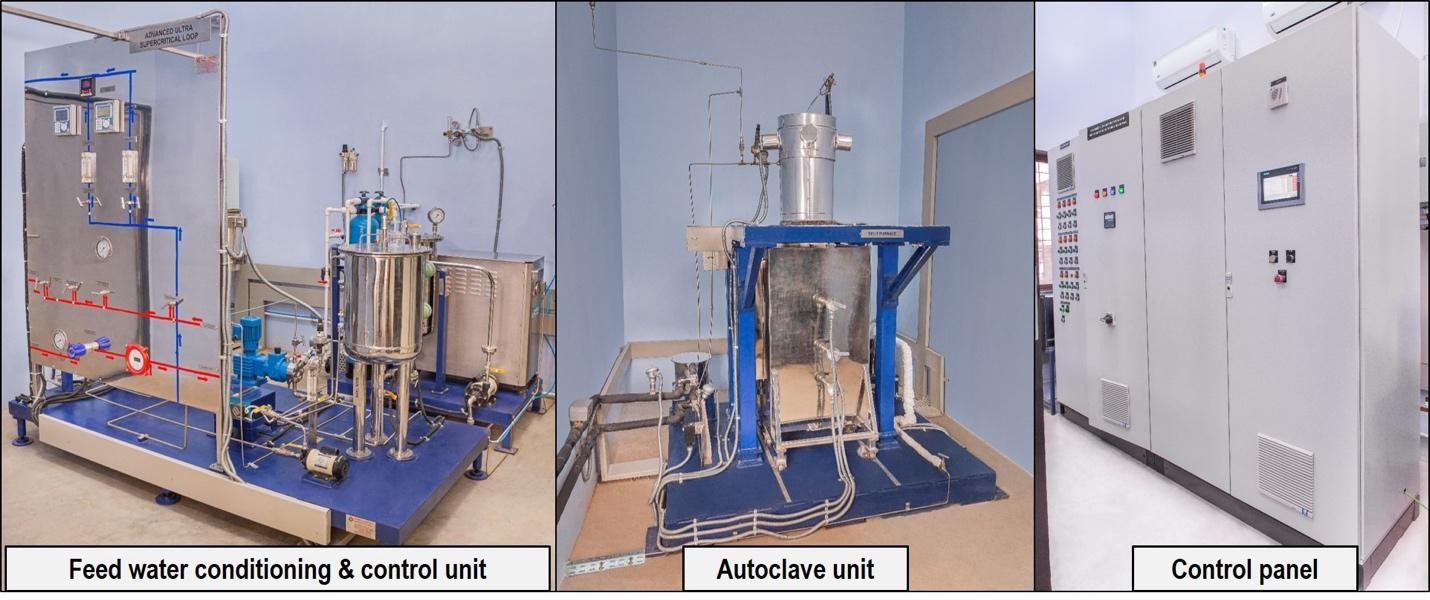

“A unique aspect of this study is that we started from scratch and the experimental setup was indigenously designed and locally fabricated by M/s Symec Engineers and this is a first of its kind study in India. Very few such setups exist across the world and this is the only one such setup in India,” notes Prof Raja.

Further, recently at the instance of Mr. S. C. Chetal, and the Department of Science and Technology on Indian Advanced Ultra Supercritical Programme, a one-day workshop to explore the utilisation of this facility by NTPC and BHEL was conducted. The development of his facility has opened up possibilities to conduct many experiments to enhance understanding of the influence of water chemistry on corrosion. After the workshop, the Department of Science and Technology (DST), Government of India has expressed interest in offering further support to collaborate with BHEL and NTPC to study the water chemistry and establish water treatment parameters for AUSC plants.

In this recent study, the oxidation behaviour of Alloy 617 was tested in the new indigenously designed experimental set-up. The researchers have shown weight gain to insignificant levels and observed an inner chromic oxide layer and outer islands of manganese, nickel or iron-based chromic oxide mineral complex (spinel) on the oxide scale – the protective layer that forms on metals to prevent further corrosion. They discovered that the oxide scale did not show any considerable presence of outer spinel due to the limited outward diffusion of the metal ions at lower temperatures, thereby, the scale protecting the underlying metal.

Previous studies had suggested internal oxidation of the Alloy 617 due to its considerable aluminium content. However, the current study in the simulated environment found that there was negligible precipitation of aluminium oxides even after 600 hours at 710 ℃.

“Although the study lasted for 600 hours, perhaps less than the operational period of power plant components, what is important is that we can understand the science of oxidation so that we can derive the parameters that could affect the corrosion process. We are now exploring other potential candidates like Alloy 740 and 304HCu, for instance,” remarks Prof Raja.

These findings present Alloy 617 as a promising candidate material for superheater and reheater tubing for AUSC technology. Its ability to maintain integrity at levels closer to AUSC conditions indicates the alloy’s potential for harnessing cleaner coal technology. Such innovations will put us another step closer towards the cleaner and energy-efficient coal-fired power plants of the future.

Further research now needs to focus on the long-term reliability of Alloy 617 under continuous operation in AUSC conditions. “As India has vast resources of coal and coal power continues to contribute to the global energy market, this research is paramount for improving the environmental sustainability of these power plants in the long-term,” notes Prof Raja. Enhancing AUSC technology could enable significant efficiency gains and emission reductions, benefiting the environment while keeping the energy sector economically productive.

The work was funded by the Mission Directorate, Advanced Ultra Supercritical Project, Government of India, and later this has also received grants from the National Project on Clean Coal Energy, Government of India and the Indira Gandhi Centre for Atomic Research (IGCAR), Kalpakkam. This has been an exciting collaboration among IGCAR Kalpakkam, NTPC, BHEL and IISc Bangalore and the research scholars Bhagwat Ghule and Sundaresan C have put in tremendous work to fructify the project.

Bhagwat Ghule, C. Sundaresan, V.S. Raja

Department of Metallurgical Engineering and Materials Science, Indian Institute of Technology Bombay, Mumbai 400076, India