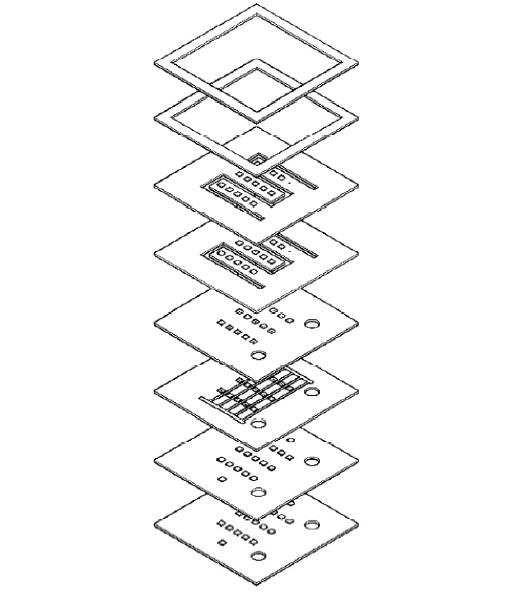

This invention relates to a packaging technique for a Micro Proton Exchange Membrane (PEM) fuel cell that ensures uniform heating. The method utilizes Low Temperature Cofired Ceramic (LTCC) technology to distribute heating across four areas, each with its own heater and thermistor. This design allows for better performance and longevity by maintaining consistent temperature. The packaging process is efficient and flexible, enabling the integration of passive mechanical components and electronics. The approach also facilitates the precise and rapid fabrication of gas distribution networks, making it suitable for portable applications. Overall, this technique reduces the size and weight of the fuel cell system while ensuring high power density and reliable operation.

The current fuel cell systems for portable applications are bulky due to the heavy graphite bipolar plates and require numerous passive and mechanical components, making them unsuitable for modern gadgets. Additionally, these systems often suffer from non-uniform heating of electrodes, leading to inefficient performance.

- The fabrication process for the gas distribution network is rapid, flexible, and precise, allowing for the creation of smaller and arbitrarily shaped channels, which enhances design versatility.

- The MEA cavity's depth can be adjusted based on the MEA thickness, ensuring it is sufficiently pressed for good electrical contacts without causing damage, leading to reliable performance.

- The LTCC technology allows for flexible routing of electrical connections and gas distribution channels, enabling multiple fuel cells to be connected in series or parallel, reducing the overall size for portability.

- Fuel inlet and outlet connections are made by brazing, providing rigid connections without the need for grooving, which reduces the ceramic bipolar plate thickness and simplifies the design.

- Heaters are distributed into four areas to ensure uniform heating, which enhances the performance and extends the lifetime of the cell by maintaining consistent temperature.

- The control logic activates heaters according to thermistor readings, ensuring uniform temperature across the cell, which optimizes the operational efficiency of the fuel cell system.

- The resistive ladder-type heater pattern printed on the ceramic layer functions both as a heater and a thermistor layer, providing dual functionality within a compact design structure.

NA

The enhanced viability of portable fuel cell systems promotes cleaner energy sources for modern gadgets. It reduces the environmental impact by minimizing the use of bulky and heavy materials like graphite.

This innovation increases the efficiency and lifespan of fuel cells, leading to less frequent replacements and reduced waste and contributes to the advancement of green technology, fostering innovation in sustainable energy solutions.

The lower overall production costs make advanced fuel cell technology more accessible to a wider range of applications. The more compact and efficient energy solutions can be beneficial for remote and off-grid communities.

- Portable electronics

- Consumer electronics

- Medical devices

- Telecommunications

- Renewable energy

- Automotive

- Aerospace

- Defense

Geography of IP

Type of IP

4146/MUM/2014

377463