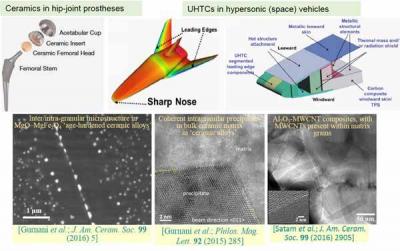

In addition to the more conventional applications, such as refractory linings of steel-making furnaces / ladles and pressurised chemical vessels,engineering ceramics, owing to their high stiffness, excellent thermal stability, relatively low density and corrosion resistance have a variety of applications as advanced structural materials in cutting tools, armor, wear resistant parts, etc. The excellent biocompatibility of ceramics (as compared to their metallic counterparts) in addition to the aforementioned properties, offer potential biomedical applications such as dental as well as hip and knee joint implants. Additionally, ultra-high temperature ceramics (UHTCs) such as TiB 2 , ZrB 2 , offering unique set of properties such as high melting point (>3000°C), hardness, elastic modulus and thermal shock resistance even at high temperatures, find applications in harsh atmospheres, such as those in space re-entry vehicles. With respect to the engineering applications of ceramics and ceramiccomposites (and also ceramic ‘alloys’), the major focus in our group at the High Temperature and Energy Materials Laboratory, IIT Bombay pertains to the defense and space applications. Some of the works are presently being carried out in collaboration with DRDO and ISRO laboratories.

Prof. Amartya Mukhopadhyay