Product development activities in the 21 st century face several challenges such as shorter product life cycles, frequent design revisions and need for shortest time to market. Globalisation has added a new dimension to this scenario forcing manufacturers to look for solutions to automate and integrate product life cycle activities. Internet has emerged an excellent tool providing interoperability among designers, manufacturers, suppliers and end users for distributed global product development.

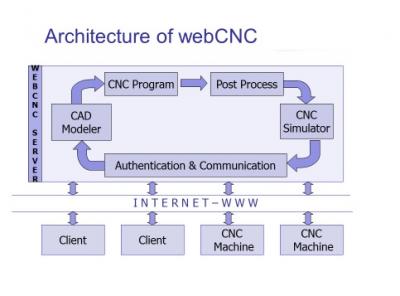

webCNC is an Internet based software for interactive part modeling and

intelligent process planning for prismatic parts commonly produced on

3-axis CNC machining centers. It has been indigenously developed at the

CAM Laboratory at IIT Bombay. Based on the Client-Server architecture, it

has four functional modules namely feature based part modeller (FBMod);

intelligent process planning (webCAPP); Graphical simulation (webSIM); and

communication for Tele-manufacturing.

The figures show the architecture of webCNC and some typical screen shots.

FBMod enables the user to interactively synthesise the 3D CAD part model

in terms of features to be machined such as Holes, Pockets, Slots, Steps,

Patterns. It provides intelligent CAD environment to validate the part model

following Design for manufacturing (DFM) philosophy. webCAPP carries out

intelligent process planning from the CAD model using Genetic Algorithm

based strategy for set up planning and operation sequencing.

The CNC part program thus created, is post processed to commercial FANUC

and ISO neutral formats to manufacture parts on the CNC machines. webSIM

provides the web based virtual simulation of CNC part program to check

the validity of the CNC part programs generated. Communication utilities

facilitate the user to up/down load the part models, process sheets, CNC

programs and simulation results.

webCNC has been hosted on the CAM server and extensively tested from

several geographical locations across the world. It provides a very robust and

reliable environment for part modeling and CNC program generation. It can

also be used as a multi user virtual laboratory for didactic purpose.

No proprietary commercial CAD/CAM/CNC software or kernel is needed to

run webCNC.

Prof. S S Pande