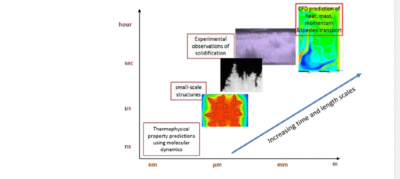

Melting and freezing phenomena are inherent to several important cross disciplinary applications such as manufacturing of cast products, welding and other fusion processing, polymer processing, food processing, and geophysical systems. These are typically multi-scale and multi-phase in nature. The final product such as an automobile piston or an ice-cream, is a result of a controlled processing of a multi-component material in liquid or semi-solid state. Thus it becomes relevant to understand the fundamental mechanisms of phase change in order to bring in improvements in manufacturing or to reconstruct the theories behind the natural manifestations. Solidification inherently involves the following: (a) heat and species transport with fluid flow (b) evolution and interaction of complex multi-phase structures and (c) deformation and shrinkage of the phases.

Our research group investigates the fundamental science behind these phenomena, and develops relevant engineering applications to reduce the production costs by controlling the material wastage and energy consumption. Some of the ongoing activities include finding answers as to how defects form in automobile and aero-engine components that are manufactured by both conventional and laser additive processing methods. The processes are observed in real-time using collaborative activities of

optical and X-ray imaging, and to develop analysis techniques. Computational models of microstructural to component levels are being developed, and linked to understand and perform extensive parametric studies.

Prof. Shyamprasad Karagadde