Reactivity initiated accident (RIA) or loss of coolant accident (LOCA) in a nuclear reactor may lead to sudden temperature rise. Accidents caused by RIA or LOCA condition may lead to a dynamic expansion of fuel pallets. This results into a multi-axial state of deformation caused by high thermal loading (1000 o Cs -1 ) in presence of extreme conditions of irradiation. Low temperature in early stage transient, metal-water reaction and accumulated irradiation in a high burn-up clad may also lead to a brittle failure. At a later stage, when clad is at high temperature for longer periods of time, internal pressure may increase leading to clad failure called ballooning.

Service life of nuclear reactors is dependent on reactor pressure vessels. Vacancy clusters and loops are generated due to irradiation. These irradiation products interact with mobile dislocations and cause increased strain hardening and embrittlement. Thus, yield stress may increase and uniform elongation may decrease. Dislocations may also annihilate some of these point defect loops and clusters leading to creation of defect free channels. These defect free channels being free of any point or line defect account for decreased strain hardening and lowering of yield stress.

For correctly predicting ductile or brittle failure in nuclear reactor, yield stress as a function of temperature, strain, strain-rate, irradiation dose needs to be modeled. Modeling the evolution of yield stress with irradiation involves development of models for evolution of these line and point defects and their interaction.

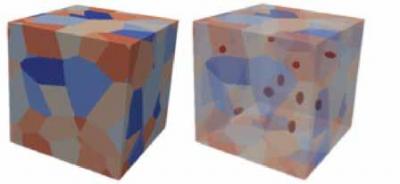

Currently empirical models calibrated against data from test reactors are used for modeling of degradation in nuclear reactor pressure vessels and their clad. Available data for calibration is limited thus limiting the predictive capability of such models. Microstructure sensitive crystal plasticity models coupled (in situ or standalone) with smaller length scale models, can predict irradiation induced defects and their effects on mechanical response.

Such models can provide useful data for aforementioned empirical models. Small length scale simulations contain information about intrinsic microstructure.

Atomistic simulations can give insight into energetics of various mechanisms. Accelerated atomistic simulations like kinetic Monte Carlo (kMC), phase field simulations and dislocation dynamics (DD) can be utilised for larger length and time domains. A crystal plasticity model coupled with smaller length scale models can predict correlations between irradiation, yield stress and temperature. Such multi-scale modeling approach can be used for prediction of crack formation and failure during LOCA condition.

Our research group is developing such multi-scale models in-house. For more information, visit www.icmeresearch.in.

Prof. Alankar Alankar