Patterns are ubiquitous in nature – such as the stripes on a cat or the dunes of sand on a beach. In many engineering materials, at length scales which can only be seen under a microscope, we often see patterns that form liked stripes or lamellar structures. In addition, many interesting shapes – such as, pyramids, cuboids, plates, and prisms – are often seen under the microscope. These patterns and morphologies that one can see under the microscope are generically known as the ‘microstructure’ of the material.It is an interesting problem to understand how microstructures form; it is also an important problem because the microstructures decide the

engineering properties of the material. Further, under service conditions, where the material is exposed to stresses and heat, microstructures evolve – leading to changes in property; typically, the properties degrade with time. Thus, the formation and evolution of microstructures is a key problem of both academic and industrial

interest in materials science and engineering. Modelling is one of the easiest, and more often than not, the cheapest way to understand the formation and evolution of microstructures. Specifically, models known as phase field models, which were developed more than sixty years ago, have become the default tools to understand the

formation and evolution of microstructures with the advent of excellent computational resources that have become available in the last two

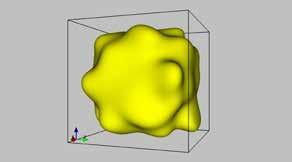

decades. In our research group, we work on translating the materials science and engineering aspects of microstructural evolution into the rigorous mathematical language (by expressing them as partial differential equations) and solving the same using numerical techniques (by writing codes and software). Some sample patterns and morphologies generated using such models and their numerical implementation are shown here.These aesthetically satisfying structures are a result of an intersection of the materials science (namely, physics and chemistry of materials) with mathematics and programming. Generating them and understanding them is intellectually both challenging and pleasurable! The project was funded by Tata Steel, General Electric, DST and DRDO, GoI; and the computational support by C-DAC, Pune and DST-FIST High Performance Computing Facility (Dendrite) at IIT Bombay.

Prof. Mogadalai P. Gururajan