Prestressed concrete (PC) members degrade rapidly when the steel strands are subjected to corrosion thereby decreasing the lifespan of the PC structure. Another problem with the use of steel strands is the loss of prestressing force in steel strands which can go up to 24% for prestressed members. Due to this there has been considerable research during the last decade to replace steel strands with Fiber Reinforced Polymer (FRP) strands, which exhibit lower long term losses and are not susceptible to corrosion. Prestressing of members using FRP strands is a relatively new technology and thus extensive research is needed to ensure the application of these strands is feasible for it to be used by designers as a substitute for steel strands in prestressing.

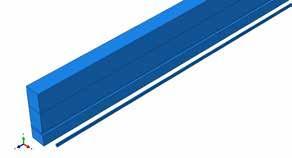

Numerical modeling of internal bond forces in prestressed concrete is complicated because it involves a number of physical and mechanical phenomena arising from the interaction of prestressing strands and concrete. Due to the composite nature of FRP strands, their behaviour is different from steel strands and involves more complicated modes of response. We are currently investigating the bond behaviour between FRP strands and concrete in pretensioned members using the modified bar scale model technique utilising commercially available finite element package (ABAQUS®). The thermal strain technique has been used to simulate the transfer of prestress force from strands to concrete in the 3D nonlinear finite element model of pretensioned members developed in this research. The simulation results are being used to critically compare the performance of FRP strands as a substitute of the conventional steel strands for prestressing of concrete members.