Pipelines are lifeline structures that provide essential services to communities by transporting water, liquid wastes,oil and gas, andpetroleum products over long distances. Nowadays, nearly 75% of the oil and petroleum products aretransported yearly by pipelines. Likewise, majority of water and gas to world’s urban centers and communitiesare transported by pipelines. Though, these pipelines, which were mainly manufactured ofplastic significantly over designed, giving us long operational lives and appreciable remaining lives.However, with increase of loads, pipeline failures have become common incurringsignificant economic, societal and environmental costs. The replacement of these old pipelines, on one handis very costly and on the other, faces significant logistical constraints in developed areas.

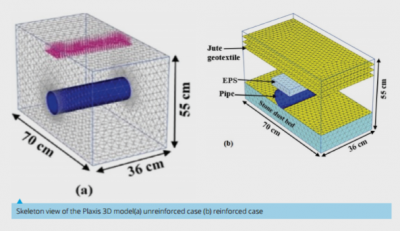

To protect the pipelines from loads laboratory model tests were conducted on pipelines buried inreinforced trench. The experiments were conducted in the test tank of size 0.7m x 0.36m 0.55 m flexible pipes buried infly ash and stone dust as backfill and bedding materials respectively.The performance of the geotextile reinforced along with geofoam inclusionfly ash bed was compared with theunreinforced bed.The experimental study was also validatedto the numerical model through Plaxis three-dimensional (3D) software.The deflection of the pipe and other performance parameters (hoop strains, bending moment and thrust)decreases significantly with the inclusion of geosynthetic material in the fly ash bed above the pipe.

Prof. J N Mandal