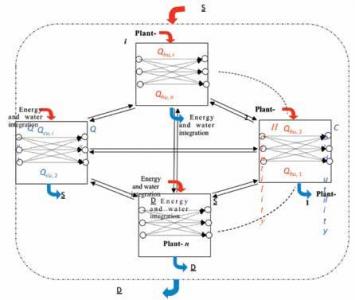

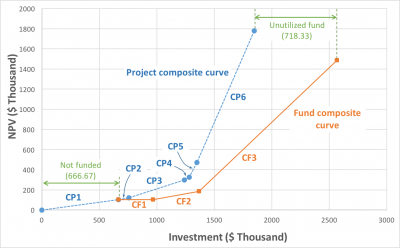

Pinch Analysis was originally developed as a thermodynamic tool to conserve thermal energy in chemical process industries through a network of heat exchangers. Over the last four decades, it was developed as a system-oriented approach for synthesising, developing, and applying methodologies to conserve resources in various industrial problems for both new and retrofit applications.Tools of Pinch Analysis help in conserving various industrial resources such as energy, water, hydrogen, waste treatment, thermally integrated water system, batch processes, raw material, carbon-footprint, aggregate production planning, chilled / cooling water systems, project planning, project financing, etc. Pinch Analysis is a conglomeration of various analytical and graphical methodologies for designing resource-integrated processes and process equipment. Analytical procedures ensure quick solution methodologies without sophisticated and costly computational packages. Graphical representations and solution procedures help in visualising the problem and addressing industrially acceptable solutions.

Significant numbers of tools have been developed by us to address various industrial level problems. Applications of Pinch Analysis have led to 10-50% conservation of energy, 10-40% conservation of water, and 5-25% reduction in operating cost in various industries world over.

Prof. S Bandyopadhyay