- TECHNICAL SPECIFICATIONS

- SPECIAL FEATURES

- WORKING PRINCIPLE

- CENTRAL FACILITY WORKSHOP PRESENTATION

- FAQ

- PUBLICATION USING DATA FROM FACILITY

- INSTRUCTION FOR SAMPLE PREPARATION

- INSTRUCTIONS FOR USERS

- INSTRUCTIONS FOR REGESTRATION

I) Load Range : Low load - upto 9.5 mN, High load - upto 500 mN

II) Displacement Range:

a) Low load: Maximum Indentation displacement (Z)- 5µm, Maximum lateral displacement - 16µm

b) High load: Max indentation displacement- 80µm

III) Low Load Resolution : Indentation 75nN, Lateral axis 3µN

IV) Displacement resolution : Indentation axis up to 0.04nm, Lateral axis up to 4nm

V) Heating/Cooling stage : Temperature range 25oC to 600oC

VI) nano- DMA (Dynamic Mechanical Analysis):

Range:

a) Frequency range: 1Hz to 300Hz (Below 10Hz, the test can take a very long time)

b) Load range : Maximum force-10000µN(10 mN)

- Load Control and Displacement Control capabilities.

- The same tip used for indentation is also used for scanning the sample.

- Can be used for testing thin films and small structures.

This FAQ deals with the different aspects of the facility. If you would like to suggest a question, do feel free to drop an email to jayabalila@iitb.ac.in.

1. What information does nanoindentation provide?

Ans: Nanoindentation provides the mechanical properties of materials like Hardness, Reduced Modulus etc.

2. How is the sample preparation done for nanoindentation? Why is the sample preparation necessary for nanoindentation?

Ans: Samples have to be flat and well-polished. Mirror polished samples are required. Sample preparation is very essential as good quality data depends on the sample preparation.

3. Why the roughness has to be less than 200nm? How do I measure the roughness of the sample?

Ans: The Berkovich tip which is mostly used has a diameter of approx 200nm therefore the roughness of the sample has to be less than 200nm. The roughness can be measured by Profilometer or AFM or any roughness measurement equipments.

4. What is the glue used to stick the sample on the stub?

Ans: The sample will be glued to the stub with the help of feviquik. Strictly no other adhesive will be used. The glue and the stub will be provided in the lab at the time of your slot.

5. Is the test destructive?

Ans: The experiment is not destructive actually, as we indent in very small region. But the sample preparation for the experiment,is glued to the stub with the help of feviquik. It can be removed by dipping in acetone or removing with the help of blade. It may get damaged during this process.

6. What is the procedure for submitting the request?

Ans: You can submit the request for Nanoindentation through Drona IRCC website. If you are applying for the slot first time you have to do a two step process. First step is, you will see your name and guide name and submit. This will be approved by your guide. Now you can fill the form and submit it. Once your PI approves your request the form will be directed to us. We will allot you the slot as early as possible. After the first time registration you just have to submit the form every time.

7. What is the usual waiting time for the slot?

Ans: The usual waiting time for the slot is one-week. During the rush-hours (like APS) it may extend to one and half week.

8. What does being a TA involve?

Ans: The job of a TA is to help us run the facility smoothly and do nanoindentation of user’s samples. You will have to do a maximum 8 hours TA duty per week. This is non-negotiable. If you are a first year PhD student with loads of coursework, we suggest that you come back after a year. The upside is that you will get really proficient in using the instrument. You will also be able to book slots during ‘off’ hours (between 6pm to 10am) to run samples for yourself or your research group. On the whole it should be a very useful learning experience for you.

9. I think I need to train as a TA. What should I do?

Ans:The first thing you should do is to check with your advisor on whether both of you agree with the time commitment. If you are a non-MEMS student, you need to contact the TA coordinator of your department to see if you could be assigned as a TA in the central facility. If the answer to both questions is ‘yes’, send an email to the convener of the nanoindenter where you want to train. We will take over from there.

10. What are the rules for getting authorized as an off-hour user for using this facility?

Ans: One student/ staff from each group can get authorized to use this facility independently in off-hours. The training will be provided only to those modes of the instrument in which the user is interested to work. After the training a final authorization test will be done and then the key permission will be allotted to the user to work in off-hours.

11.. What happens if one violates the rules of the facility?

Ans: The person is barred from entering the facility initially for two weeks.

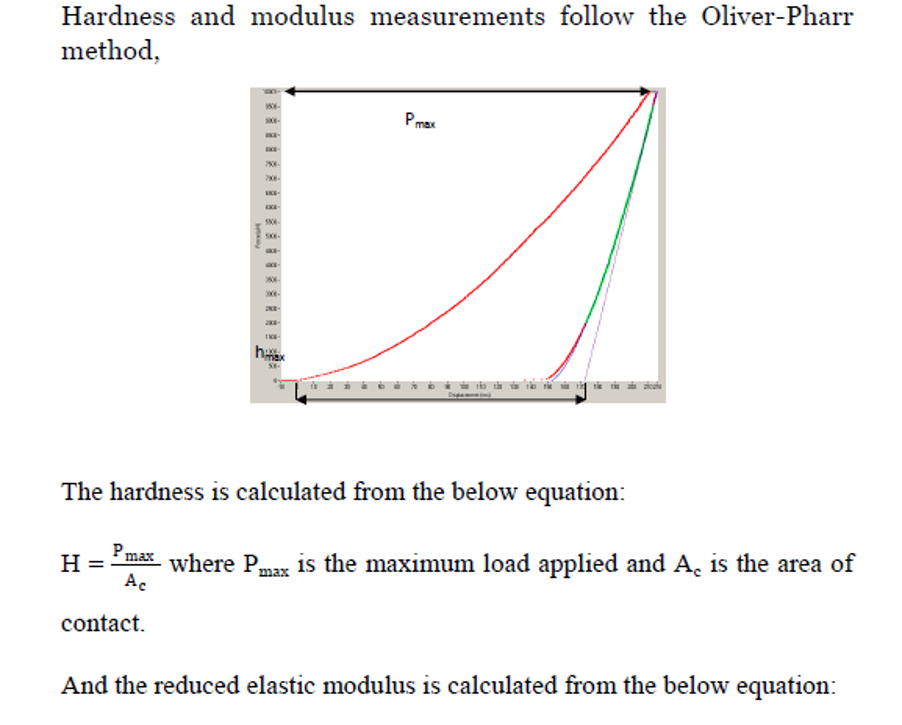

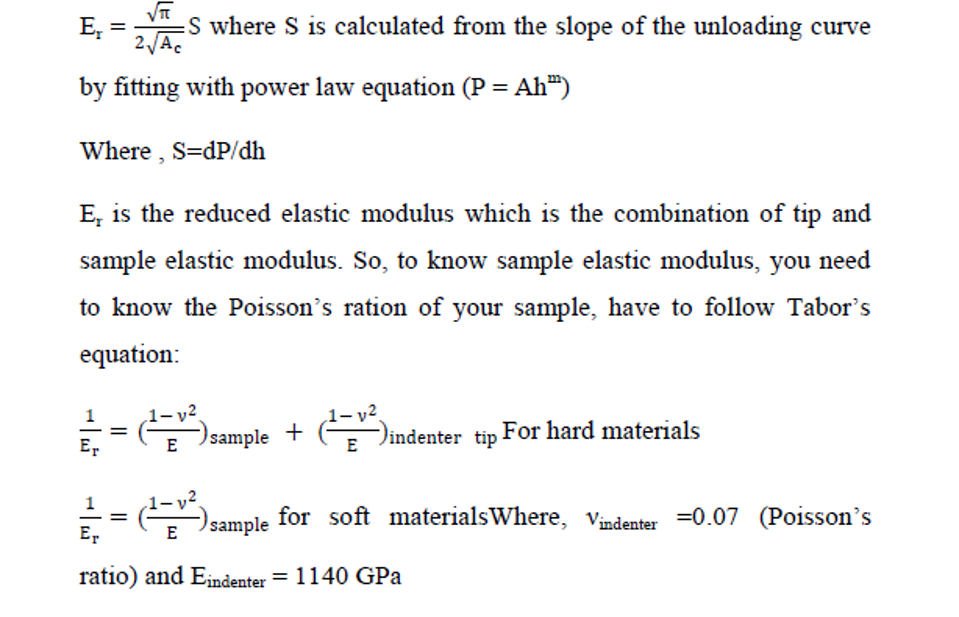

12. How is the nanoindentation data analysis done?

Ans:

How to analyze the Nanoindentation data

FOLDER: Each folder bearing the sample name contains the data related to the sample done at all conditions.

The folder contains three types of files:

- hys file

- txt file

- all data file

SUB-FOLDER:

1) The (.hys) file is the software file which could not be opened without the Hysitron software.

2) The (.txt) file is the text file of all the data points to give load-displacement-time curve. You can open it in excel and plot the load-displacement/load-time/displacement-time curve.

3) The ‘all data file’ has to be opened in excel sheet. This is the main file which contains all the output values such as Hardness, Reduced modulus, Stiffness etc.

TERMS: Important Terms in the all data file:

Pmax = Maximum Applied Load (μN or mN)

S = Stiffness at maximum depth (μN/nm)

hmax = Maximum Depth of penetration (nm)

hc = Contact depth of penetration (nm)

Er = Reduced Elastic Modulus (MPa or GPa)

H = Hardness (MPa or GPa)

Ac = Projected Contact area (nm2)

heff= the depth at 0 uN load from power law equation

m = power law equation coefficient

A= Power law equation constant

hf = final depth

-------------------------------------------------------------------------------------

1) Verma, S., Sarkar, P., & Pant, P. (2021). Thermal drift in room temperature nanoindentation experiments: Measurement and correction. Journal of Materials Research, 36(17), 3436-3444.

2) Kolay, S., & Bhargava, P. (2022). Role of MgO in lowering glass transition temperature and increasing hardness of lithium silicate glass and glass-ceramics. Ceramics International.

3) Nanda, G., Chandran, N., Babu Thiyagarajan, G., Devasia, R., & Kumar, R. (2022). Mechanical response and thermal expansion characteristics of spark plasma sintered Zr–La–B–C (O)-based precursor-derived ceramics. Advances in Applied Ceramics, 1-8.

4) Basu, S., Samajdar, I., Patra, A., Jaya, B. N., Microstructural Engineering in Dual Phase Steels - Partitioning Aspects and Correlation to Formability, TMS 2022

5) Mathews, N. G., Venkataramani, N., Jaya, B. N., Extrinsic and intrinsic size effects on deformation and fracture in Barium Titanate’, EUROMAT 2021

- Sample roughness has to be less than 200nm.

- Loose particles or thin films with porous coatings will not be entertained.

- Powder samples will not be done. If pellet can be prepared of the powder by sintering then it can be done.

- Liquid samples cannot be done.

- Optical microscope available in the machine for optically locating the sample is 10x and 50x.

- Preliminary literature survey has to be done for the respective experiment and the user must be aware of the parameters to be used for his samples. If the sample is unknown then the parameters can be optimized by us.

- Absence for the slot without prior information to the Nanoindeter lab will lead to debar of the student from another registration for 15days. Twenty minutes past the time of slot allotted will be treated as cancelled.

- User should not apply for the slot if the sample is not ready.

- Roughness value is mandatory and should be reported before the slot is allotted.

- The user must have optical image/SEM image of the sample who are interested to do experiment on the specific location.

- The slot timing is divided into morning slot from 9:30am to 1:30pm and afternoon slot will be from 2pm to 6pm. If your samples are not completed in this time slot, then you have to apply for a fresh slot and book another slot. Time will not be extended for any user. Depending on the load function and the type of tests the timings will be scheduled.

- Data will be given only in CDs or DVDs. It has to be brought by the user. Data collection time is from 9:30am to 9:45am and from 5:30pm to 5:45pm in weekdays.

- Sample stubs should be returned to the lab immediately. If not returned, the data will not be provided to the users.

- The user should be present at the time of the slot.

- You can request for two consecutive slots only once in a week. If your experiments need more time then please drop a mail to nanoindenter@iitb.ac.in and cc to jayabalila@iitb.ac.in. We can accordingly allot you a slot.

- Slots will be provided as per the queue.

- For cantilever bending experiments and resistance measurement experiments one full day slot will be given. For High temperature tests, the slot will be allotted for two consecutive days to each user.

- For High temperature tests, the user has to inform one week earlier so that the slot can be scheduled for two consecutive days. The set up and the calibration may take more than half a day. The slots for temperature tests may take time as it will run only once a month.

- Scanning of the sample/SPM imaging of indents takes time. Slower scanning rates may consume maximum an hour. Therefore, in the time slot whatever images possible to scan will be given.

- For scratch tests or some specific tests, if the desired tip is unavailable with us the user can get their own tip which can be fixed in our transducer.

- Beyond 100 indents for high temperature testing, the user has to arrange for their own high temperature tip.

- Beyond 50 scans for scratch + imaging condition, the user has to bring their own tips.

- For TA’s and Independent users for usage of the machine after official hours and non-working days:

i) Off-hour users can do measurements only on their own samples. For other users, a separate requisition form needs to be submitted even if off-hour time is to be allotted.

ii) We will ban the users who are caught doing some other samples and the person whose sample they are doing for the entire year.

iii) One week prior you have to inform about your experiments and the materials needed for your experiment is mandatory. Your requisition has to be there one week before on the basis of which a slot will be allotted to you on off-hour which you can do on your own.

Type of Indenters available

NANOINDENTER MEMS, IITB

| Sr.no | Indenter Type | Diameter (nm/µm) | Type | Shape |

| 1 | Berkovich | ~200nm | Low load | Three sided pyramidal |

| 2 | Berkovich | ~ 700nm | High load | Three sided pyramidal |

| 3 | Conical | 100µm | Low load | |

| 4 | Berkovich tip Temperature tip | ~200nm | Low load | Three sided pyramidal |

| 5 | Sapphire sphere | 1000 µm | Low load | Spherical |

| 6 | Sapphire sphere | 1000 µm | High load | Spherical |

| 7 | Cube corner | 90° | Low & High | |

| 8 | Acoustic emission(Cube corner) | ~200nm | Low load | Cube corner

|

Note: Old Berkovich tips (worn out) can be used for scratch tests (low load/high load) if no quantitative analysis is needed.

|

Definition of one sample for a particular test:

- 1 slot = 40 indents (Low/High load RT)

- 1 slot = 15 scratches (Low/High load RT)

- 1 slot = *5 scanning images for indents/scratches (Low load)

i) For scanning rate from 1Hz to 3Hz - 5scanning images

ii) If the scanning rate is below 0.4 Hz, the scanning may take more than 45minutes. - 1 slot = 10 nano DMA indents (RT Low Load)

- 1 slot = 5 indents (Low load, High temperature-only in scanning mode) = 5 high temperature indents

- For any additional tests not listed here, the charges will be on slot hour basis. A maximum of four hour will be considered as

one slot.

| Revised charges per slot (Rs.) | ||||

| Category | ||||

| Type of experiment | Internal users | External academic | National R & D labs | Industry & Other Non govt. agencies |

Nanoindentation/Scratch (Without imaging)

| 1,500/- | 3,000/- | 7,500/- | 15,000/- |

Nanoindentation/Scratch (With imaging)

| 1,500/- | 3,000/- | 7,500/- | 15,000/- |

Nano-DMA

| 1,500/- | 3,000/- | 7,500/- | 15,000/- |

| High temperature indentation | 2,500/- | 5,000/- | 12,500/- | 25,000/- |

| Additional tests defined by the user | 3,000/- | 6,000/- | 15,000/- | 30,000/- |

Note: 1) For Internal students: The TA’s of the instrument and independent off-hour users will be charged 50% of the rate that are fixed for Internal users.

2) For High temperature tests, 1 sample= 5 indents is considered for the same sample. No exchange of sample possible.

-----------------------------------------------------------------------------------------------------

- Only one registration will be accepted at a time.

- User has to be present when the slot has been allotted while testing the samples.

- Users please note that if your samples are not ready at the time assigned to you for Nanoindentation then you will lose your slot and cannot apply for another slot for one week. You must inform us at least 24 hours in advance if for some unavoidable reason samples will not be ready for Nanoindentation at the time assigned to you - in tha+t case we will reassign a slot and no penalty will be imposed.