This invention describes a two-photon patternable all carbon material system which can be used to fabricate fluorescent 3D micro/nano structures using two-photon lithography, with sub-wavelength resolution. The synthesized material system eliminates the need to use conventional two-photon absorbing materials such as two- photon dyes or two-photon initiators. Additionally, there is no requirement of any additional fluorophore to attain emissive traits in the resin and the polymerized structures. The carbon dots in the resin offer high signal to noise ratio in fluorescent imaging, which is further incorporated for non-invasive imaging and 3D reconstruction of polymerized structures.

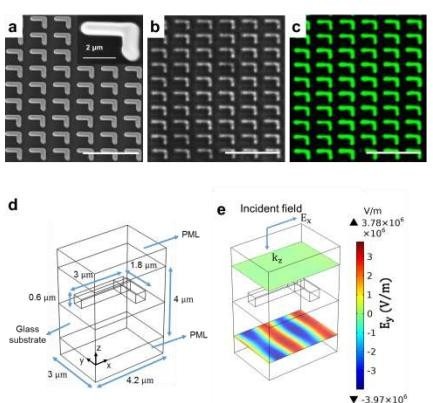

Figure 1. Depiction of (a) SEM image of the fabricated structure and inset shows a zoomed view of single element, (b) Optical image of an array of L-shaped chiral metastructures fabricated in ACCR20, (c) Fluorescent image of the 25 metastructures array shown in (b), (d) Computational model of showing a unit cell of the L-shaped chiral metastructures and (e) Computational model showing the presence of Ey field component in the transmitted field. Scale bars in (a-c) are 10 μm.

The high cost, limited availability, and complex processing requirements of commercial two-photon polymerization (2PP) resins such as the Nanoscribe IP-series hinder their widespread use in academic and industrial microfabrication. Additionally, the need for improved resolution, sensitivity, and multifunctionality in photoresists calls for innovative materials with tunable photophysical properties. There is a pressing need for cost-effective, easily synthesized, and high-performance alternatives for sub-diffraction micro/nanofabrication.

- Intrinsic Photoinitiation: Carbon dots act as built-in photoinitiators within the resin, enabling efficient polymerization without requiring additional chemical initiators, simplifying the formulation and reducing toxicity.

- Strong Two-Photon Absorption: The composite resin exhibits excellent two-photon absorption properties, allowing precise and high-resolution 3D micro/nanofabrication using femtosecond laser lithography techniques.

- High Spatial Resolution: The fabricated microstructures achieve feature sizes as small as 200–300 nanometers, enabling intricate and complex designs suitable for advanced photonic and biomedical devices.

- Multifunctional Optical Properties: The printed structures retain bright and stable fluorescence under UV and visible light, which can be leveraged for sensing, imaging, and optical tagging applications.

- Cost-Effective and Scalable: The resin formulation uses low-cost, sustainable materials and simple synthesis methods, making it a scalable alternative to expensive commercial photopolymer resins.

- Compatibility with Commercial Systems: It is designed to work seamlessly with existing commercial two-photon polymerization setups like Nanoscribe, facilitating easy integration into current manufacturing workflows.

The developed prototype consists of a novel acrylate-carbon dot composite resin (ACCR), where carbon dots synthesized via a bottom-up hydrothermal method are uniformly dispersed in a photopolymerizable acrylate matrix such as polyethylene glycol diacrylate (PEGDA). This resin formulation exhibits suitable viscosity, stability, and two-photon absorption properties for high-resolution 3D micro/nanofabrication using femtosecond laser-based two-photon lithography (e.g., 780 nm, ~100 fs pulse width). The carbon dots serve as intrinsic photoinitiators, enabling efficient polymerization without the need for external initiators. Using a commercial 2PP setup (e.g., Nanoscribe), complex microstructures such as pillars, lattices, and helices have been successfully fabricated with feature sizes down to ~200–300 nm. The printed structures exhibit bright fluorescence under UV and visible excitation, confirming the retention of optical activity post-fabrication. This prototype demonstrates a scalable, low-cost, and multifunctional alternative to commercial resins for advanced microfabrication.

The technology is at the stage of early prototype development and/or validation in relevant environment.

5

This technology democratizes high-resolution nanofabrication by offering a cost-effective, simplified process accessible to academic labs and small industries. It advances photonics and biomedicine through rapid prototyping of micro-optics, bio scaffolds, and sensors, while its eco-friendly formulation reduces toxic waste and environmental impact. Additionally, it supports STEM education by providing affordable training tools in advanced photonics and microfabrication.

- Micro/Nanofabrication

- Optoelectronics

- Biomedical Engineering (e.g., tissue scaffolds, drug delivery microdevices)

- Photonic devices and Metamaterials

- Lab-on-a-chip and MEMS/NEMS

- Academic research and prototyping labs

- 3D Printing and advanced manufacturing

Geography of IP

Type of IP

202221052488

428692