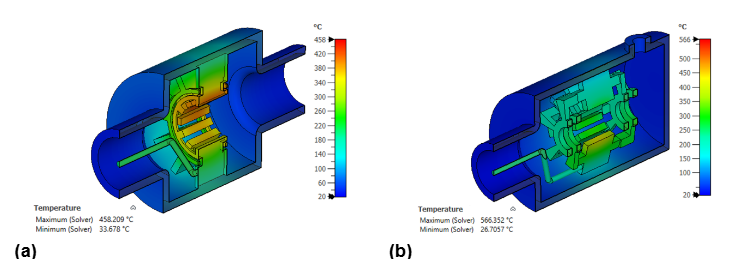

This technology introduces a novel strapping configuration for cavity magnetrons to improve their thermal performance, especially in high-power applications. By repositioning the strap rings farther from the anode vanes and connecting them through specially designed L- or T-shaped supports, the design reduces thermal stress, enhances mechanical stability, and maintains desired RF performance. This modification is particularly beneficial in continuous wave (CW) operations, where heat buildup can affect conventional designs.

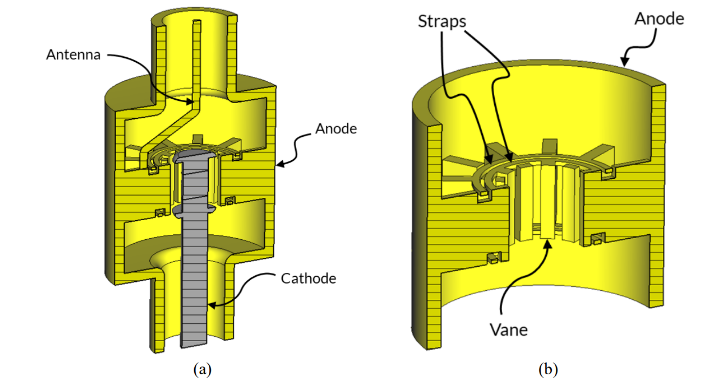

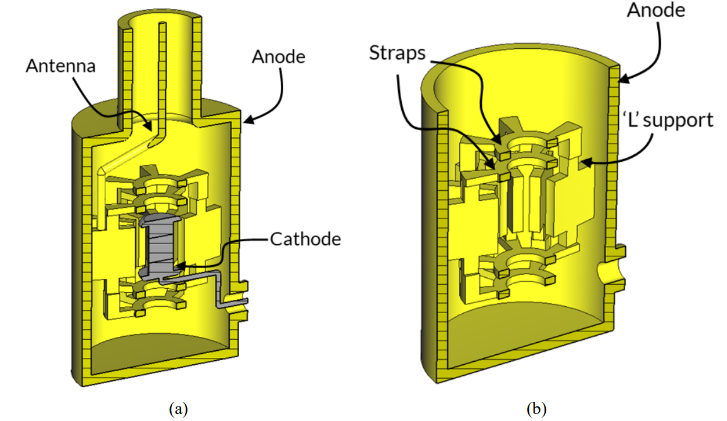

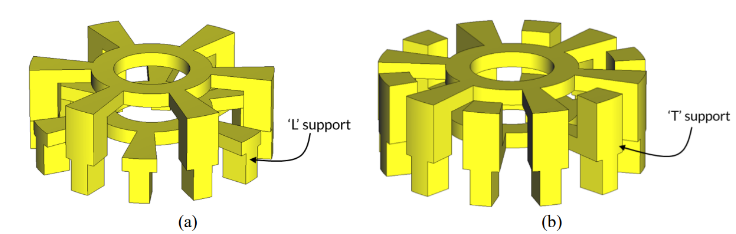

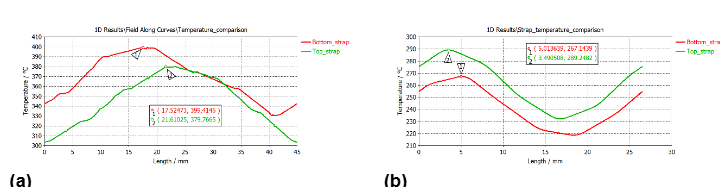

Figure (1a) Magnetron cut section showing the cathode in a typical double-ring strapped anode, (1b) Anode cut section showing straps in typical double ring strapping form; (2a) Cut section of the magnetron with proposed strapping design, (2b) cut section of anode showing proposed strapping design; (3a) Proposed strapping design with 'L' supports, (3b) Embodiment of the proposed design with 'T' supports for the lower strap; (4) Temperature profile of a magnetron with (4a) Conventional strapping and (4b) Proposed strapping; (5) Temperature on straps of the magnetron with (5a) Conventional strapping and (5b) Proposed strapping.

In conventional magnetron designs, thin metal straps used for π-mode operation are positioned close to the anode vanes. These straps often face intense heat due to proximity to electron bombardment zones, making them vulnerable to deformation or failure - especially under high continuous power loads. This leads to instability in output frequency and potential device breakdown. A new approach is needed to improve thermal resilience while preserving electromagnetic functionality.

- Strap Placement to Reduce Thermal Stress: The straps are positioned farther away from the electron-interaction region, which effectively reduces the thermal stress experienced by the components during operation.

- Uniform Strap Ring Size and Suspension: Strap rings are designed to be identical in size and are suspended over the vanes using L- or T-shaped supports, ensuring structural consistency and stability.

- Use of Thicker Straps for Enhanced Durability: This specific configuration supports the use of thicker straps, which significantly improves durability, especially under high-power conditions.

- Support Design Increases Inter-Strap Capacitance: The L- or T-shaped supports are engineered to increase the inter-strap capacitance, contributing positively to the stability of the π-mode operation.

The prototype comprises a magnetron assembly with symmetrically arranged cylindrical anode vanes, a central cathode, and two strap rings (top and bottom) held in position by angular L- or T-shaped supports. These supports ensure structural balance and help maintain π-mode integrity by precisely managing inter-vane connectivity and strap placement. Simulations and physical models validate enhanced thermal tolerance and electromagnetic performance.

An innovative magnetron design incorporating a uniquely engineered strapping configuration has been developed to enhance performance characteristics such as thermal stability and performance. The design was extensively studied using electromagnetic simulations, confirming its potential advantages over conventional configurations. This work formed a part of a doctoral research project and has been successfully defended as part of a PhD thesis. The findings contribute to the theoretical understanding of magnetron behavior and offer a promising direction for future high-power microwave source development.

Although no physical prototype has been built yet, the simulation results strongly support the feasibility of the concept. The current status of the technology is at a simulation-validated stage. Plans can be made to transition the design toward experimental fabrication and testing if any party is interested. This will help establish practical performance metrics and further refine the design for real-world applications.

3

This innovation enables more robust, long-lasting magnetrons, which are critical components in radar, industrial heating, and medical devices like cancer therapy machines. By improving reliability and reducing maintenance or failure rates, the technology can enhance performance in defence, healthcare, and manufacturing sectors.

- Radar systems (military and civilian)

- Industrial microwave heating

- Medical RF therapy and diagnostics

- Plasma processing

- Satellite communication and aerospace

Geography of IP

Type of IP

202221025748

547933