The invention discloses a scalable ball milling-based method to synthesize Sn-Bi alloy electrodes for sodium-ion batteries. The process overcomes limitations of Sn anodes by using Bi as a buffer to mitigate volume expansion, thus enhancing cyclic stability and rate capability.

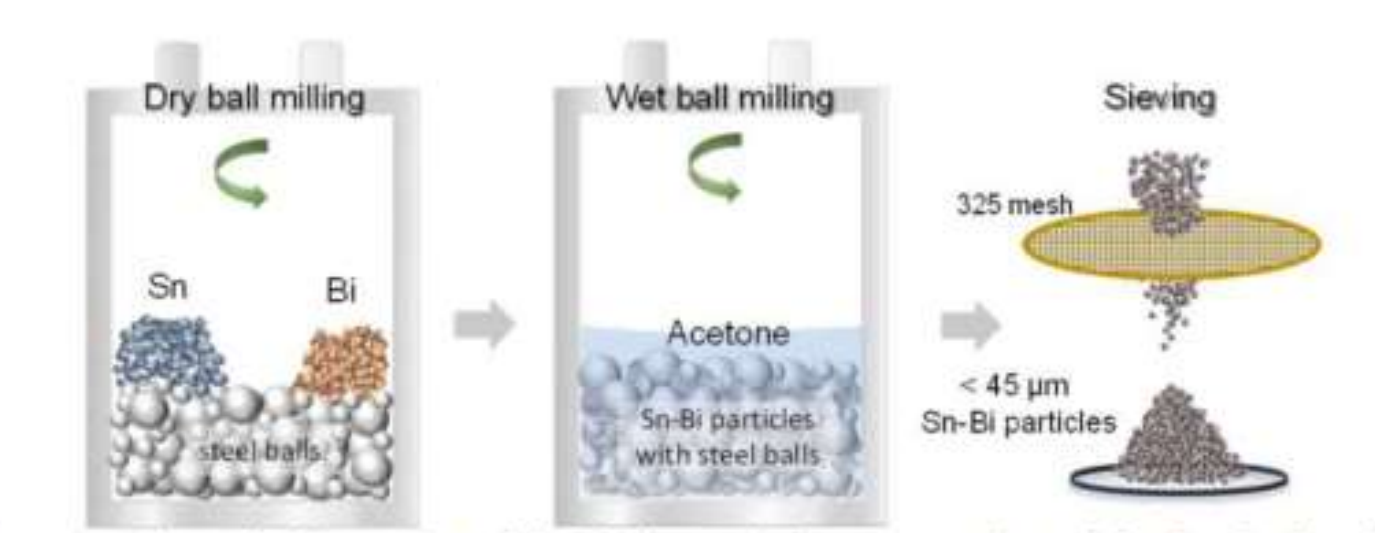

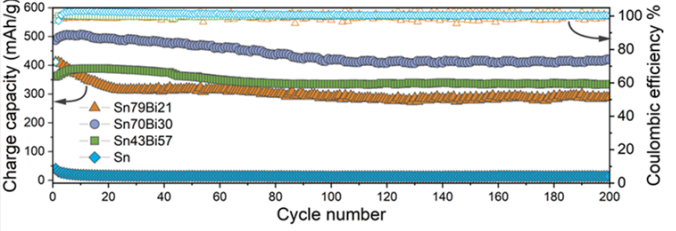

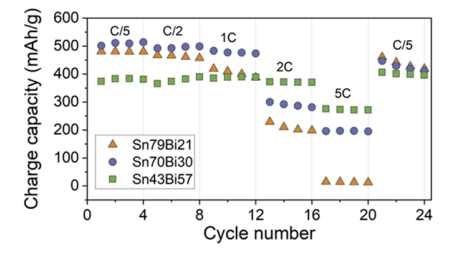

Figure (1) Synthesis process for Sn-Bi compositions involving dry ball milling, wet ball milling, and sieving; (2) Cyclic stability, along with CE, during galvanostatic cycling at 1 C for the Sn-Bi ball-milled materials; (3) Rate capability, expressed in terms of the charge, when the current density is varied from C/5 to 5 C and back to C/5

Conventional tin (Sn) anodes in sodium-ion batteries suffer from rapid capacity fade due to severe volume changes during cycling, resulting in mechanical failure and reduced battery life.

- Enhanced Cyclic Stability: The Sn-Bi alloy electrodes retain 70%–92% of their initial capacity after 200 charge-discharge cycles, ensuring long-term battery performance.

- Superior Rate Capability: These electrodes maintain high charge capacities even at fast charging rates up to 5 C, making them suitable for high-power applications.

- Particle Morphology Control: The combination of dry and wet ball milling followed by sieving produces uniform alloy particles < 45 μm, ensuring consistent electrochemical behavior.

- Green Manufacturing: The process uses water-based binders and avoids hazardous solvents, making it environmentally friendly and safe for large-scale use.

- Cost-Effective and Scalable: The method employs low-cost raw materials and simple milling equipment, making it economically viable and scalable for industrial production.

- Improved Mechanical and Electrochemical Properties: The addition of bismuth buffers the volume changes in tin during cycling, reducing mechanical stress and enhancing electrode durability.

- High Na-Ion Diffusivity: The Sn43Bi57 composition exhibits excellent sodium-ion diffusivity, leading to improved rate capability and overall battery performance.

Lab-scale sodium-ion cells using Sn-Bi electrodes were assembled and tested. The fabrication includes slurry casting, drying, and cell assembly in the glove box. Electrochemical testing confirms improved performance over pure Sn anodes.

4

This innovation addresses the need for affordable and sustainable alternatives to lithium-ion batteries, especially for large-scale energy storage, contributing to energy equity and clean technology transitions.

- Electric Vehicles (EVs) and e-Mobility: Fast charging, long cycle life batteries

- Renewable Energy Storage: Stable storage for solar and wind energy

- Consumer Electronics: Longer-lasting power for portable devices

- Grid Stabilization and Backup Systems: Reliable energy buffering and backup

- Industrial and Portable Power Solutions: Efficient storage for tools and off-grid use

Geography of IP

Type of IP

202421048280

561495