This invention presents a method for preparing a potassium (K)-rich iron (Fe)-based polyanionic fluorophosphate (KaFebPcO4F) cathode material with a stoichiometry of ~1.80–2.2:0.98–1.1:0.97–1.04. The material shows high capacity (~97 mAh/g at C/10), electrochemical stability, and is synthesized using eco-friendly precursors. A corresponding cathode and K-ion battery configuration are also disclosed.

The growing need for sustainable and low-cost energy storage has intensified the search for alternatives to lithium-ion batteries. However, most K-ion battery cathodes explored so far involve toxic or expensive metals like vanadium, and their structural/electrochemical stabilities are limited. There is a need for environmentally friendly, high-performance cathode materials made from earth-abundant elements.

- Environmentally Friendly Materials: The cathode is made from iron, replacing toxic and costly vanadium with safer, earth-abundant elements.

- Simple, Low-Energy Synthesis: It is produced through a straightforward solvothermal process at 200°C, followed by a brief exposure to a potassium-containing solution, making it energy-efficient and scalable.

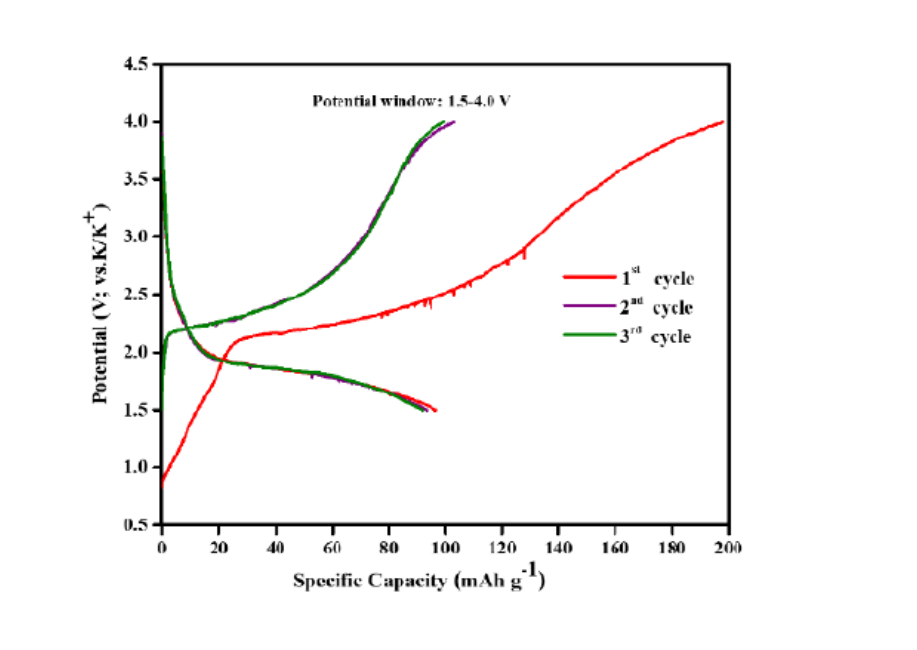

- Electrochemical Stability: The material maintains around 80% of its capacity after 25 charge-discharge cycles and operates reliably within a voltage window of 1.5 to 4.0 V.

- High Specific Capacity: It delivers an initial discharge capacity of approximately 97 mAh/g at a C/10 rate, indicating strong energy storage performance.

- Air-Stable and Easy to Handle: The cathode material is stable in air, eliminating the need for special handling or storage conditions, which enhances its practicality.

The prototype cathode is fabricated by mixing the synthesized material with multi-walled carbon nanotubes, conductive carbon additives, and a PVDF binder in a 7:2:1 mass ratio. This mixture is cast as a slurry onto aluminum foil, dried, and assembled in CR2032 coin cells. Electrochemical tests confirm stable performance, with a mass loading of 2–2.5 mg/cm².

4

The technology offers a sustainable alternative to lithium- and vanadium-based battery systems by using earth-abundant and non-toxic materials. It contributes to the development of safer, cleaner, and more accessible energy storage solutions, supporting environmental goals and energy equity.

- Energy Storage: Can be used in stationary energy storage systems to support grid stability and renewable energy integration

- Electric Vehicles (EVs): High capacity and stability make it suitable for rechargeable batteries in electric mobility applications

- Consumer Electronics: The cathode material can power devices like smartphones, laptops, and wearable tech with safer and longer-lasting batteries

- Renewable Energy Systems: Enables efficient storage of solar and wind energy, ensuring reliable power supply even during off-peak generation

- Battery Manufacturing: Offers a sustainable, cost-effective alternative for cathode production in next-generation potassium-ion batteries

Geography of IP

Type of IP

202421041662

562348