This invention presents a new type of electrocoalescer designed to efficiently separate water from water-in-oil emulsions, especially those found in crude oil processing. The device uses a non-uniform and time-varying electric field applied across two electrodes with very different surface areas. This setup creates strong electrical forces that pull water droplets together more quickly, helping them merge and separate from the oil. The design not only speeds up water removal but also reduces the chances of short circuits and equipment damage, making the process safer and more reliable.

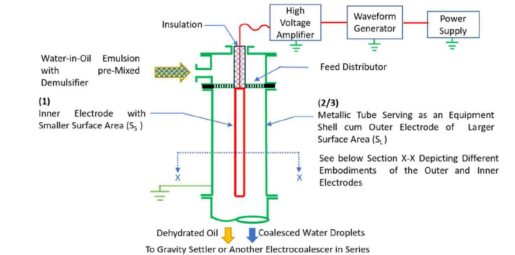

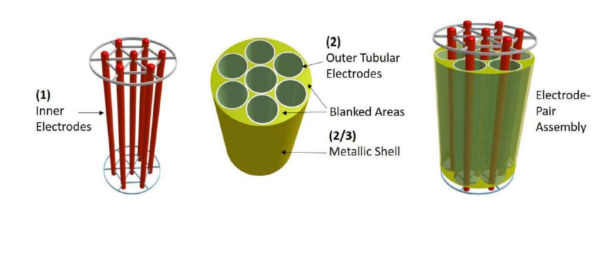

Figure (1) Schematic showing a vertical electrocoalescer using coaxial electrodes to separate water from oil under a modulated electric field; (2) 3D model illustrating a modular assembly of coaxial electrode pairs within a metallic shell for scalable emulsion separation; (3) Laboratory prototype of the coaxial electrocoalescer, connected to a function generator and high-voltage amplifier for emulsion separation using time-modulated electric fields

Electrocoalescer is widely used in petroleum refineries to separate water from crude oil emulsions. However, existing designs often struggle with slow separation rates, the formation of conductive water droplet chains that cause electrical short circuits, and inefficiencies when processing low-quality or viscous crude oils. Current systems either use uniform electric fields or require expensive demulsifiers, leading to high operational costs and limited effectiveness.

- Non-Uniform Electric Field Design: The device uses a pair of electrodes with highly unequal surface areas, producing a strongly non-uniform electric field. This focused field distribution increases the strength of electrohydrodynamic and dielectrophoretic effects, significantly improving the rate at which dispersed water droplets migrate and coalesce.

- Positive Dielectrophoresis for Droplet Collection: Water droplets suspended in oil are more polarizable than the surrounding medium, and under a non-uniform electric field, they experience positive dielectrophoretic force. This causes them to move toward the smaller, high-field electrode, where they accumulate and merge, leading to faster and more complete water separation.

- Time-Modulated Electric Field: Instead of using a constant voltage, the system applies a modulated signal that alternates between high and low field strengths. This time variation prevents droplet chaining or overaccumulation, improves stability, and enhances droplet detachment from the electrode surfaces, increasing the throughput of the system.

- Optimized Electrode Geometry: The device developed has coaxial geometry. The surface area ratio between the large and small electrodes (SL/SS) is a critical design variable, with values as high as 15:1 shown to deliver optimal performance in coalescence rate and completeness.

- Enhanced Dehydration Performance: Experiments with model emulsions demonstrated up to 85% water separation in 290 seconds under time-modulated fields. This performance surpasses that of traditional electrocoalescers operating under constant fields and without optimized geometries.

- Scalable and Modular Architecture: The design allows for modular stacking of electrode pairs within a shared shell, making it well-suited for industrial-scale implementation. This enables either batch or continuous processing and allows customization of capacity depending on throughput requirements.

The prototype developed is a vertical-axis, cylindrical electrocoalescer housed in a tubular insulating casing. The design incorporates a central stainless steel rod as the high-voltage electrode and a surrounding stainless steel mesh cylinder as the grounded electrode. These electrodes have substantially different surface areas, forming a strongly non-uniform electric field along the vertical axis of the chamber. This field configuration enables efficient application of positive dielectrophoretic forces, which drive water droplets in oil emulsions toward the high-field zone near the central rod, promoting rapid coalescence and phase separation.

The system was operated using a modulated voltage, alternating between high and low field strengths. Experimental tests with water-in-sunflower oil emulsions demonstrated that an SL/SS (large-to-small electrode surface area) ratio of 15 enabled 85% water separation in just 290 seconds, outperforming conventional constant-voltage electrocoalescers. A modular shell design allows for stacking multiple such units to achieve scale-up. Additional measurement features, such as a visual separation column, were integrated for monitoring the water phase separation during operation.

The technology has been successfully demonstrated and validated at laboratory scale. Controlled experiments with different electrode geometries, surface area ratios, and voltage modulation patterns consistently confirmed the enhanced performance over traditional systems. The dehydration efficiency increased markedly with higher field gradients and proper modulation. The system is now ready for pilot-scale trials, further design optimization, and adaptation for industrial-scale deployment in both upstream and downstream oil processing units.

4

This innovation offers significant advantages in terms of operational efficiency, environmental impact, and safety. By minimizing the need for chemical demulsifiers and improving separation kinetics, the device reduces chemical dependency, lowers energy use, and extends equipment life. It is especially beneficial for processing opportunity crudes and low-API feedstocks, which are becoming more common in global refining. The enhanced separation reduces downstream corrosion and maintenance issues, contributing to sustainable refining practices. Its modularity and adaptability also open doors for use in water treatment and other industrial separation processes beyond petroleum, making it a broadly applicable, clean-tech solution.

- Petroleum refining and desalting

- Oil and gas field processing

- Any system involving water oil emulsions, including biofuel refining, cosmetics, transformer oil dehydration, oil cooled transformers

- Chemical processing units involving phase separation

- Enhanced separation in electrohydrodynamic systems

Geography of IP

Type of IP

202221026167

552892