A new transformer design embeds a thin, high-permeability magnetic tape layer interleaved/interposed within its windings. This “magnetic leakage layer” stores and releases extra magnetic energy when power levels change, so the transformer automatically adapts its internal “leakiness” based on load. Computer simulations show it can boost efficiency, shrink size, and simplify power converter designs. The claimed invention of achieving variable leakage inductance need no extra sensors, switches, or moving parts.

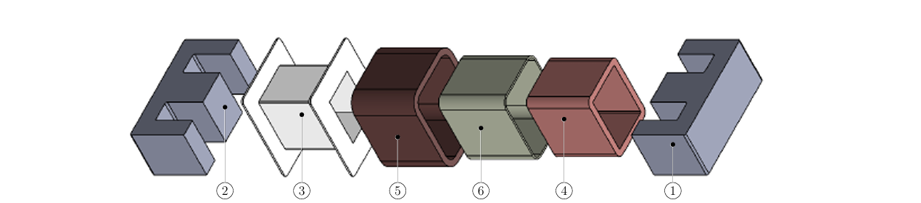

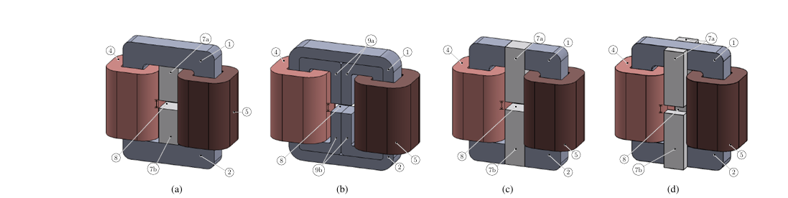

Figure (1) Assembly of the proposed leakage inductance integrated design of a two-winding transformer having shell-type winding; (2) Prior Arts: Different configurations of a two-winding MF/HF transformer reported in literature having structures with separate windings members and 5 , additional leakage layers and an airgap, member 8, (a) leakage layer, derived from I-cores: upper and lower sections, members 7a and 5 4 7b, (b) leakage layer, derived from U/C-cores: upper and lower sections, members 9a and 9b, (c) leakage layer. derived from I-cores and placed between two core halves, and (d) leakage layer: derived from I-cores and placed outside the main cores.

Medium/high-frequency (MF/HF) transformers are vital in modern power electronic (PE) converters used in critical applications like renewable energy systems, EVs, and aerospace. Some high-power converters, such as resonant and dual active bridge DC-DC converters, rely on the transformer's leakage inductance for optimal operation and high power density. However, conventional methods to increase leakage inductance by adjusting winding geometry or spacing increase winding volume and reduce power density. Existing techniques for variable leakage inductance are bulky, complex, and costly, often requiring additional windings, control circuits, or mechanical parts.

Therefore, there is a need for a simple, scalable MF/HF transformer design that enables variable leakage inductance without external components or complex controls.

- Automatic Load-Responsive Operation: This design uses a flexible magnetic tape layer inside the windings so the transformer’s leakage energy rises automatically as demand falls no external controls required.

- High Energy Density in a Compact Size: This feature delivers higher energy storage per volume, enabling a smaller, lighter transformer without sacrificing power capacity.

- Improved Thermal Management: This innovation also improves heat removal from inner windings, cutting hot spots and enhancing long-term reliability.

- Simplified Manufacturing and Lower Cost: This approach eliminates reliance on air gaps or extra bias circuits, keeping manufacturing simpler and costs lower.

The design has been fully modeled in 2-D finite-element magnetic software and tested in MATLAB/Simulink within an isolated dual-active-bridge dc-dc converter setup. These virtual prototypes confirm the leakage layer’s ability to achieve variable inductance with respect to the load and improve soft-switching range at light loads.

The design has been fully developed and tested through advanced computer-based simulations. Prototyping is in progress.

4

Widespread use of this simple, self-tuning transformer can cut size, weight, and component count in renewable-energy inverters, electric-vehicle chargers, and industrial power supplies. Lower losses and better thermal control translate to reduced energy waste, longer equipment life, and lower system costs—helping accelerate cleaner, more affordable power technology.

- Medium- and high-frequency DC-DC converters

- Dual/Multi-active-bridge power supplies

- Series/parallel resonant converters

- Solar-inverter and wind-turbine power stages

- Electric-vehicle on-board chargers

- Industrial drives and robotics power modules

Geography of IP

Type of IP

202421010877

557231