The invention presents a low-cost, solvent-assisted additive manufacturing process for high-temperature polymer materials (HTPM), specifically Polyetheretherketone (PEEK) and its composites. In this method, commercial PEEK is dissolved in a solvent to form a gel-like solution, which is then 3D printed layer-by-layer into a coagulation (to convert gel into solid/semi-solid) bath containing a non-solvent. Through solvent and non-solvent exchange, the polymer structure solidifies at room temperature, eliminating the need for high-temperature processing. The process enables fabrication of semi-crystalline PEEK parts with reduced warping, shrinkage, and energy consumption.

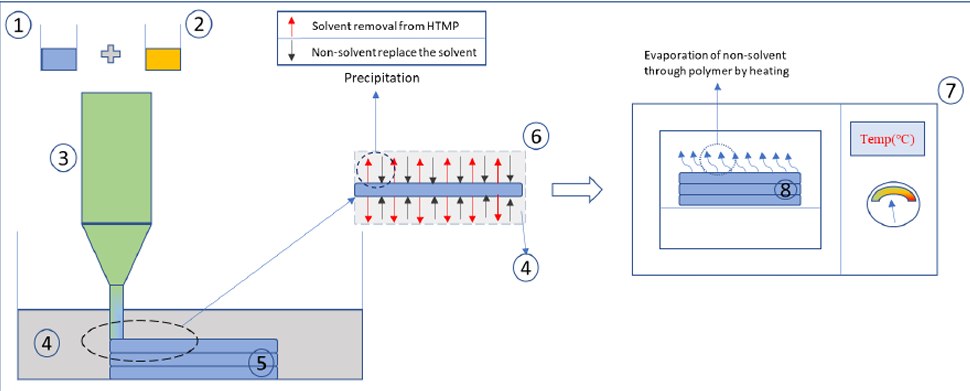

Figure (1) Schematic view of the Additive manufacturing process according to present invention [wherein 1. HTPM 2. Solvent 3. Polymer and Solvent solution 4. non-solvent 5. Additive Manufacturing at room temperature 6. Polymer Phase Change (Liquid to solid) through precipitation 7. Vacuum Oven Heating for non-solvent and trapped solvent removal 8. HTPM]; (2) 3D printing of HTPM-PEEK/solvent solution (a) directly on the surface, (b) immersed in non-solvent bath (parts shown after taking out from bath)

Conventional additive manufacturing of high-temperature polymers like PEEK requires high processing temperatures, costly equipment, and suffers from thermal degradation, warping, and poor bed adhesion. Existing techniques also involve multi-step processes, binder-based systems, or modified polymer chemistries.

Therefore, there is a need for a simplified, cost-effective, and low-temperature 3D printing method using commercially available PEEK that overcomes these challenges while maintaining the material’s superior thermal and mechanical properties.

- Solvent-Assisted 3D Printing: The process described uses a gel-like PEEK solution formed by dissolving commercial PEEK in organic solvents, deposited layer-by-layer into a coagulation bath.

- Low-Temperature Manufacturing: It enables 3D printing of semi-crystalline PEEK and composites below 40°C, eliminating the need for high-temperature processing, thus reducing operational energy consumption.

- Cost-Effective Process: It avoids expensive machinery required for FFF (Fused Filament Fabrication) or other high-temp methods, significantly reducing setup and operational costs for individual unit.

- Controlled Porosity and Mechanical Properties: Porosity and mechanical properties of the structure can be controlled by changing 3D printing parameters like printing speed, nozzle pressure, layer thickness also by changing concentration of solvent and non-solvent (changing exchange/diffusion rates).

- Simple, Easy Automation and Scalable: Unlike multi-step conventional methods, it reduces manufacturing complexity, is easily automated, and highly scalable.

- Sustainable and Eco-Friendly: The solvent-assisted layer-by-layer deposition allows for precise control and minimal excess material, unlike subtractive manufacturing methods and the solvents used for dissolving high-temperature polymer materials (HTPM)-PEEK can often be recovered and reused, minimizing environmental impact.

NA

Work is ongoing on a similar patent related to this technology.

3

This low-temperature, solvent-assisted 3D printing method for High-Temperature Polymer (HTPM)–PEEK composites promotes sustainable and responsible manufacturing. By reducing energy consumption and enabling material reuse, the process minimizes environmental impact. Its ability to produce biocompatible, lightweight parts at low cost makes advanced medical and aerospace technologies more accessible, enhancing public health and safety while supporting eco-friendly innovation.

- Biomedical

- Aerospace

- Automotive

- Electronics

- Filtration and Environmental

- Defense

- Manufacturing industry

Geography of IP

Type of IP

202421028146

557067