The invention relates to a continuous flow process for the preparation of organic nitrate esters by reacting liquid or solid aliphatic polyhydroxy compounds with nitrating acid in a microreactor. The process enables continuous production of both solid and liquid nitrate esters. It is simple, safe, efficient, economically viable, easily scalable, and delivers high product yields.

Conventional batch processes for synthesizing organic nitrate esters are unsafe, inefficient, and difficult to scale due to their exothermic nature, poor heat dissipation, long reaction times, and high risk of decomposition and runaway reactions. Existing continuous methods are either complex or use corrosive reagents. A safer, simpler, and scalable method with high yield and better process control is urgently needed.

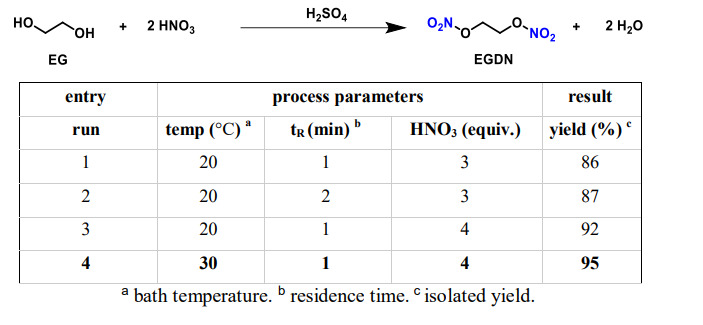

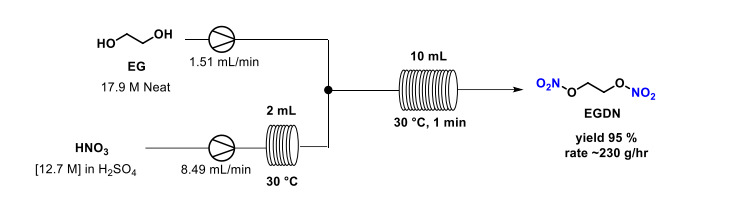

- Continuous Flow Nitration: The present invention provides a continuous flow nitration process using tubular microreactors for the preparation of organic nitrate esters by mixing polyhydric alcohols with nitrating acid under controlled conditions.

- Enhanced Safety: The use of microreactors significantly minimizes the reaction hold-up volume, which reduces the risk of decomposition and prevents runaway reactions during the highly exothermic nitration process.

- High Yield and Productivity: The developed process achieves high isolated yields of over 90% and space-time yields (STY) exceeding 18 g/h/mL for all tested nitrate esters, demonstrating its efficiency and industrial viability.

- Versatility: The same microreactor setup has been successfully used to synthesize a wide range of nitrate esters including dinitrates (e.g., DEGDN), trinitrates (e.g., TMETN), and tetranitrates (e.g., ETN) by varying the polyol feed and reaction parameters.

- On-Demand Production: The process enables on-demand and flexible manufacturing due to its low residence time of approximately 1 minute and the ability to rapidly switch between different nitrate esters without modifying the reactor setup.

- Temperature Control: The microreactor design, having a high surface-to-volume ratio, provides efficient heat removal, which is essential for maintaining the desired reaction temperature and avoiding product degradation during the nitration.

- Solid & Liquid Feed Compatibility: The process can handle both liquid polyols (e.g., ethylene glycol, DEG, TEG) and solid polyols (e.g., TME, ET) by employing suitable feed protocols, such as direct pumping for liquids and dissolution in sulfuric acid for solids.

The prototype consists of a continuous flow microreactor system using PFA tubing with an internal diameter of 1 mm and volume of 2 mL. Reagents, including liquid or sulfuric acid–dissolved polyols and nitrating acids, are fed using syringe pumps into a TEE junction for mixing. The reactor and conditioning loops are immersed in a temperature-controlled bath to maintain precise reaction temperatures between 10°C and 80°C. Quenching is done inline using ice water, and products are isolated by layer separation or filtration. The same setup was used for synthesizing various nitrate esters with high yield and productivity.

The process has been successfully validated in the laboratory for multiple nitrate esters with over 90% yield and space-time yields above 18 g/h/mL, using a single unmodified microreactor setup across all syntheses.

5

The invention significantly enhances process safety in the production of energetic materials by reducing the risk of decomposition and runaway reactions through continuous flow nitration. It minimizes hazardous inventory, ensures better temperature control, and enables safer handling of reactive intermediates, thereby lowering the likelihood of industrial accidents. The technology supports inherently safer, scalable, and economically viable manufacturing, addressing long-standing safety concerns in nitrate ester production.

- Propellant and explosive manufacturing

- Energetic material synthesis

- Pharmaceutical and medical nitrate compounds

- Fuel additive production (e.g., cetane improvers)

- Chemical process industries involving nitrate esters

- Defense and aerospace sectors requiring high-energy materials

Geography of IP

Type of IP

202321041020

559720