This technology introduces a novel class of nanocomposite hollow fiber membranes (HFMs) using hydrophilic ZIF-8/GO (ZGs) nanohybrids embedded in polymer matrices such as PES. These ZGP HFMs demonstrate significantly enhanced hydrophilicity, hemocompatibility, cell compatibility, antifouling, and separation performance. Applications span biomedical devices, water purification, and gas separations, including CO2 capture.

Current hollow fiber membranes (HFMs) suffer from inadequate hydrophilicity and poor compatibility with biological fluids. The hydrophobicity of high-performance fillers like ZIF-8 restricts their use in biomedical applications. There is a pressing need for membranes that combine superior separation with biological compatibility.

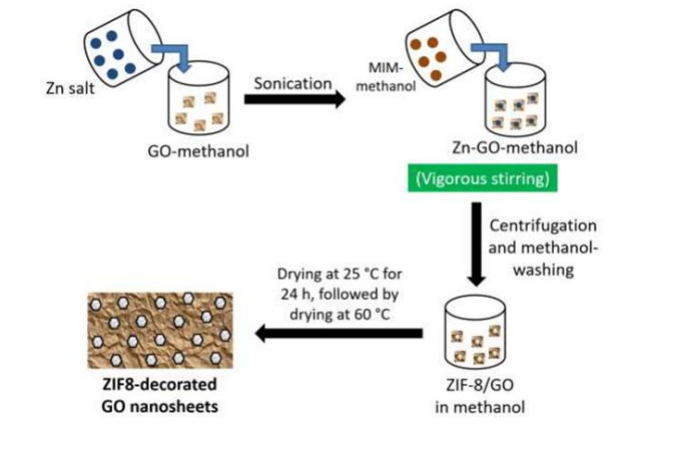

- ZIF-8/GO Nanohybrid (ZGs): This Enables the incorporation of high-performance zeolitic imidazolate framework 8 (ZIF-8) into hydrophilic membranes by anchoring it onto graphene oxide nanosheets, overcoming ZIF-8’s inherent hydrophobicity.

- Improved Hydrophilicity: The water contact angle significantly reduced from 77.6° to 51.4°, leading to better wettability and reduced fouling—essential for biomedical and filtration uses.

- Superior Hemocompatibility: This method demonstrates hemolysis below 0.2%, low SC5b-9 complement activation (~6 ng/mL), and prolonged clotting times, making it safe for blood-contact devices.

- Enhanced Cell Compatibility: It supports strong adhesion and proliferation of L929 and HepG2 cells, with increased markers like urea and albumin—indicating potential in tissue engineering and liver-assist systems.

- Advanced Separation Performance: Exhibits high pure water flux (KUF ~392 mL/m2/h/mmHg), MWCO (Molecular Weight Cut-off) around 130 kDa, and excellent antifouling with FRR above 84% and low protein adsorption.

- Gas Separation Capability: Achieves ideal selectivity for CO2/CH4 up to ~80 and CO2/N2 up to ~100, surpassing Robeson’s upper bounds—suitable for carbon capture and industrial gas separation.

There are five variants (ZGP-25 to ZGP-100) developed using in-house spinning. Epoxy-potted lab-scale HFM modules fabricated and validated for biomedical, water, and gas separation performance.

The laboratory demonstration has been successfully completed and is ready.

4

This technology enables safer and more effective biomedical devices like dialysis and liver-support systems. It enhances access to clean water through efficient ultrafiltration. It also contributes to climate solutions via low-energy CO2 separation. Overall, it improves healthcare, environmental protection, and industrial sustainability.

- Biomedical Engineering & Point-of-Care Devices: Integration into compact, wearable, and portable medical devices requiring high safety and selective permeability

- Dialysis & Bioartificial Organs (BAL): Compatible with hepatocyte-based systems for liver support and bioartificial organ development

- Tissue Engineering & Cell Culture: Porous, biocompatible scaffolds supporting large-scale cell attachment and proliferation

- Bioprocessing & Pharmaceutical Manufacturing: Sterile and selective membranes for protein separation, clarification, and virus removal

- Water & Wastewater Treatment: Advanced ultrafiltration membranes for suspended solids, bacteria, and organic compound removal

- Industrial Gas Separation & Environmental Technology: Selective membranes for CO2 capture, O2/N2, and CO2/CH4 separation processes

Geography of IP

Type of IP

201721046576

385659