This is a cutting-edge solid-state elastocaloric cooling technology utilizing NiTi Shape Memory Alloys (SMA) to address the environmental and energy efficiency challenges posed by traditional Vapor Compression (VC) systems. Unlike conventional systems that rely on high Global Warming Potential (GWP) refrigerants, this innovative solution operates without refrigerants, significantly reducing greenhouse gas emissions. The technology incorporates advanced designs featuring cyclic devices driven by linear actuators and copper blocks for enhanced heat transfer, achieving high heat recovery effectiveness. By integrating heat and work recovery mechanisms, the system delivers superior energy efficiency and performance at larger temperature lifts, making it a sustainable and effective alternative for various cooling applications.

The traditional Vapor Compression (VC) cooling systems significantly contribute to global warming due to their use of high Global Warming Potential (GWP) refrigerants. These systems are energy-intensive, leading to high operational costs and increased greenhouse gas emissions. With stricter environmental regulations and the urgent need for sustainable solutions, there is a critical requirement for an alternative cooling technology that is more energy-efficient and environmentally friendly, capable of providing effective cooling while minimizing the environmental impact, and compliant with future refrigerant regulations.

- The invention leverages solid-state elastocaloric cooling using NiTi Shape Memory Alloys (SMA), offering a significant advancement over traditional VC systems.

- The system operates without refrigerants, eliminating the use of high GWP substances. Thus, it is environmentally friendly with significantly reduced greenhouse gas emissions.

- The integration of heat and work recovery mechanisms enhances the overall energy efficiency, enabling the system to achieve higher Coefficients Of Performance (COP) even at larger temperature lifts.

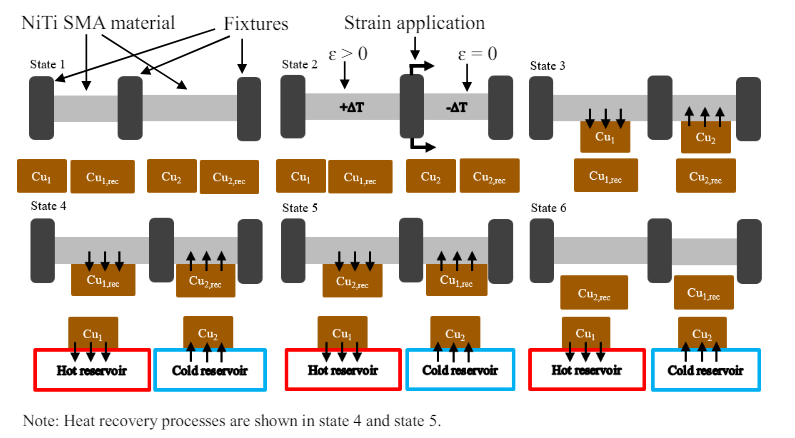

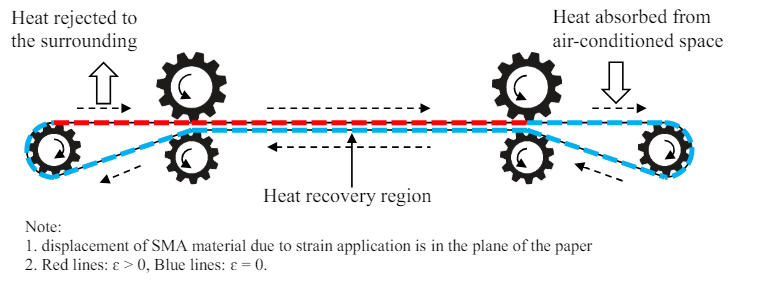

- The technology features cyclic devices driven by linear actuators and copper blocks for superior heat transfer. These designs maximize heat recovery effectiveness, setting it apart from other solid-state cooling methods such as magnetocaloric and thermoelastic cooling, which face limitations in cooling power and cost.

- The use of NiTi SMA materials and the system's scalable design make it suitable for a wide range of cooling applications, from residential air conditioning to automotive climate control and portable electronic cooling devices.

The prototypes utilize NiTi SMA materials with specific dimensions (e.g., 100mm × 6mm × 1mm) and are designed to operate with high thermal contact conductance and strain rates. The designs include cyclic devices with copper blocks to maximize heat recovery effectiveness, achieving specific cooling rates and temperature lifts under controlled conditions.

3

Adopting this technology can significantly reduce greenhouse gas emissions and energy consumption in cooling applications, contributing to environmental sustainability, and compliance with stricter regulations on refrigerants.

The technology can be applied in various domains such as:

- Residential and commercial Heating, Ventilation, and Air Conditioning (HVAC)

- Refrigeration units

- Automotive climate control systems

- Potentially, portable electronic cooling devices

Geography of IP

Type of IP

202021052154

487823