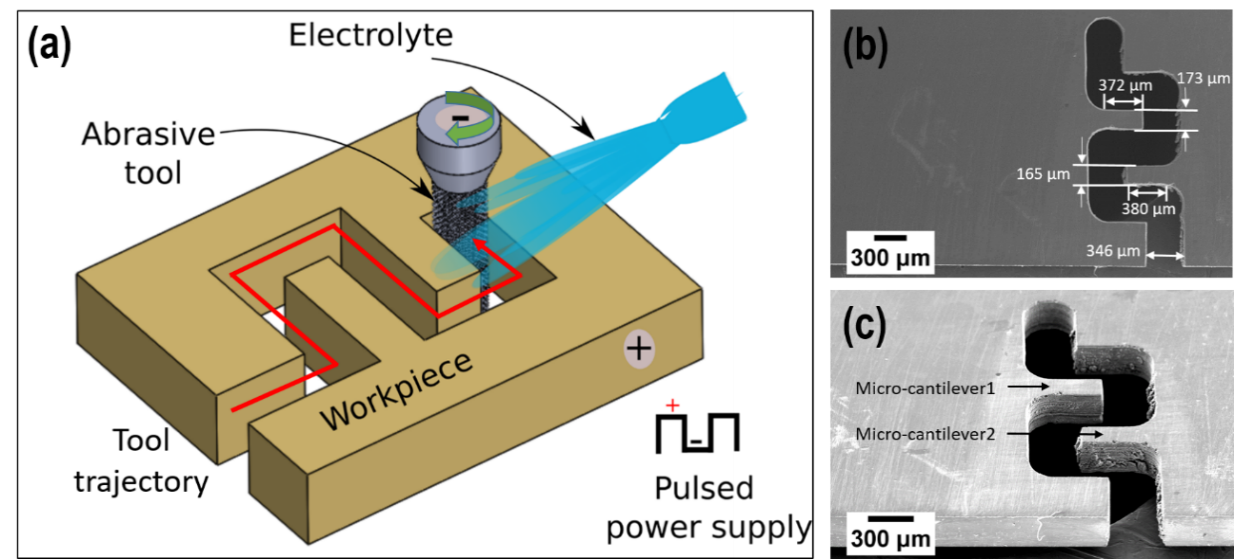

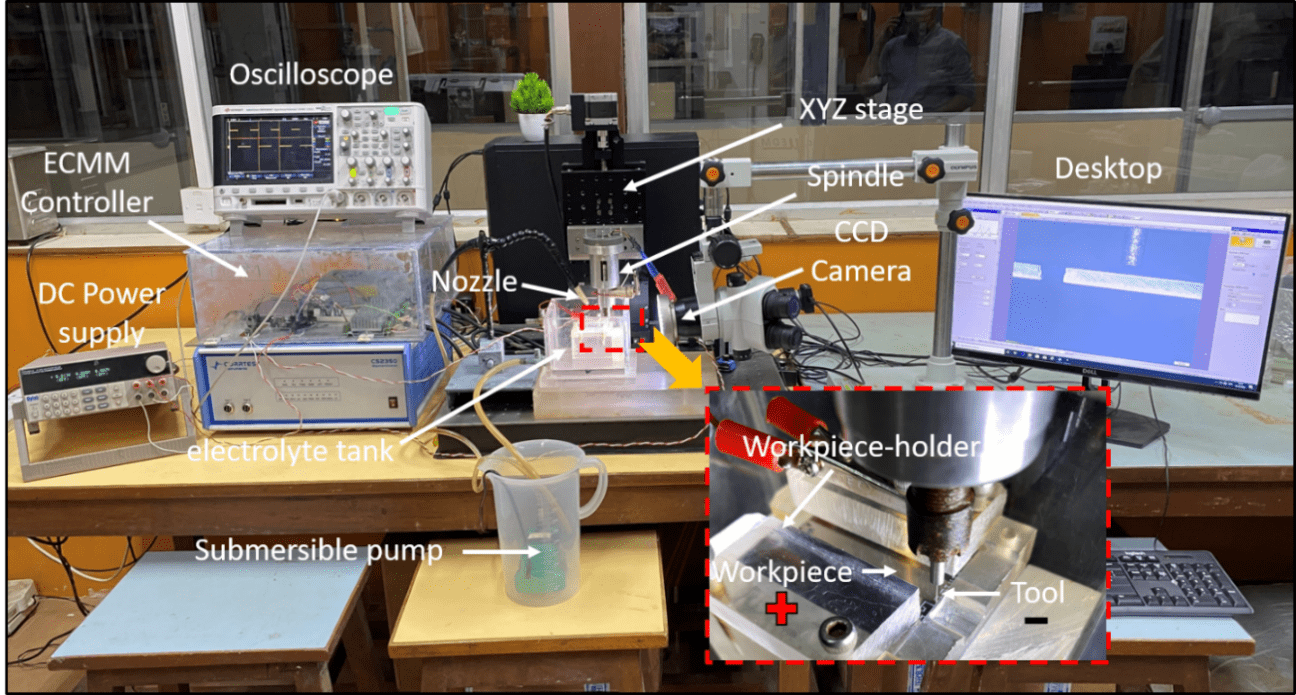

The present invention is a hybrid electrochemical micromachining (ECMM) system designed to enhance the surface characteristics of titanium alloy parts by reducing oxide layer formation during machining. This advanced system uses multiple electrodes and pulsed voltage supply to improve the precision and accuracy of machined micro-features.

Current electrochemical micromachining (ECMM) methods face challenges with reproducibility and accuracy due to issues like inhomogeneous current density distribution, resulting in pitted surfaces. Machining titanium alloys is particularly problematic because of the rapid formation of a dense oxide layer, which degrades machining stability and surface quality.

- Improved precision and accuracy: The 5-Electrode system utilizes multiple electrodes, including workpiece, tool, counter electrode, reference electrode, and auxiliary electrode, for better localized machining and dimensional accuracy.

- Reduced oxide layer formation: Dual pulse generation circuit provides forward pulses to the tool and reverse pulses to the auxiliary electrode to manage oxide layer formation. The auxiliary electrode with reverse polarity effectively removes the oxide layer, enhancing surface quality.

- Enhanced control: Bi-potentiostat maintains a stable potential for precise control of the machining process.

- Safe: Current sensor monitors real-time machining current to detect and prevent short circuits.

- Automated process: The microcontroller unit automates the process and minimizes human interaction.

- Environmentally friendly: The use of non-acidic electrolytes like sodium bromide (NaBr) ensures health safety and reduces machine degradation.

The technology is in an advanced stage of development, with the system components and their integration fully conceptualized and described.

6

The invention promises to significantly enhance the precision manufacturing capabilities for critical applications in aerospace, medical, and micro-device industries, leading to better-performing products with higher reliability and safety standards.

- Aerospace industry for complex shapes from hard-to-machine alloys

- Biomedical devices, including orthopedic and dental implants

- Automotive industry

- Electronics

- Micro-electromechanical systems

- Manufacture of microholes, micro-nozzles, and precision microdevices

Geography of IP

Type of IP

202021030168

505359