The present invention describes a low-cost, high-temperature gripper designed for polymer testing. These grippers are lightweight, easy to process, and essential for understanding polymer behavior under stress and temperature conditions, particularly during manufacturing processes.

When testing polymers at high temperatures, the material often softens and slips from the gripper. Current solutions, such as hydraulic grippers, are expensive and don't provide an easy method to adjust clamping force without disrupting the testing environment.

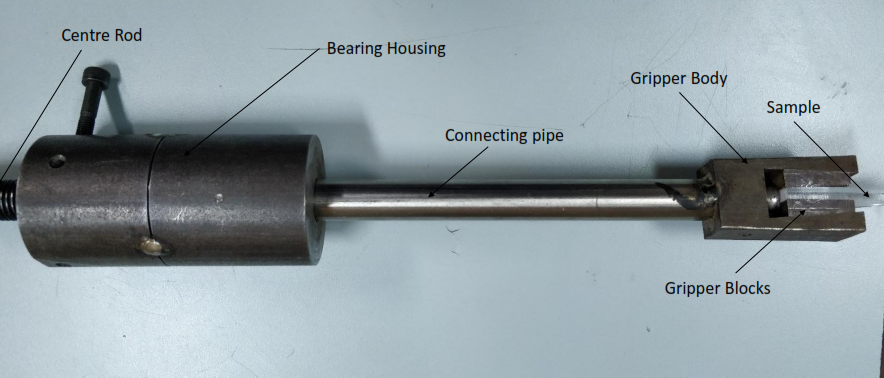

- The innovation has grooved wedge-shaped gripper blocks that slide on internal walls of the gripper body.

- It allows for clamping force adjustments (via a rotating bearing housing) without disturbing the environment inside the furnace.

- It is cost-effective and can be integrated with existing tensile testing machines.

- It ensures accurate test results by preventing polymer slippage and maintaining a consistent thermal environment.

The prototype includes two thrust bearings, a bearing housing, closing plates, pins, and a gripper assembly. It effectively holds test samples within a furnace environment while allowing for easy adjustments from outside.

The gripper design is at the prototype stage, showing promising results in maintaining test conditions and providing accurate measurements.

7

This technology can lead to better quality control in polymer manufacturing, reducing material waste and improving product performance. It supports advanced research in materials science, contributing to technological innovation.

- Polymer manufacturing and processing

- Mechanical testing of polymers at high temperatures

- Research and development in materials science

Geography of IP

Type of IP

202021037234

484040