This patent outlines a method and system for optimizing surface parameters of substrates coated with thin films to improve their hydrophobic properties. The method involves analyzing the shape of a liquid drop on the substrate outside the deposition chamber to record changes in the drop's shape. These changes, related to the distance of the drop from the substrate surface, help determine variations in surface parameters corresponding to different thin film thicknesses. The optimal thickness of the thin film is identified to maximize hydrophobicity, which is crucial for applications like semiconductor device manufacturing.

The existing methods for estimating surface wettability and energy are either post-fabrication or complex and partial in nature. These methods do not provide accurate predictions of surface wettability before the fabrication process, which can lead to inefficiencies and increased costs in semiconductor device manufacturing.

- Drop Shape Analysis: Performed outside the deposition chamber to record changes in the shape of a liquid drop on the substrate

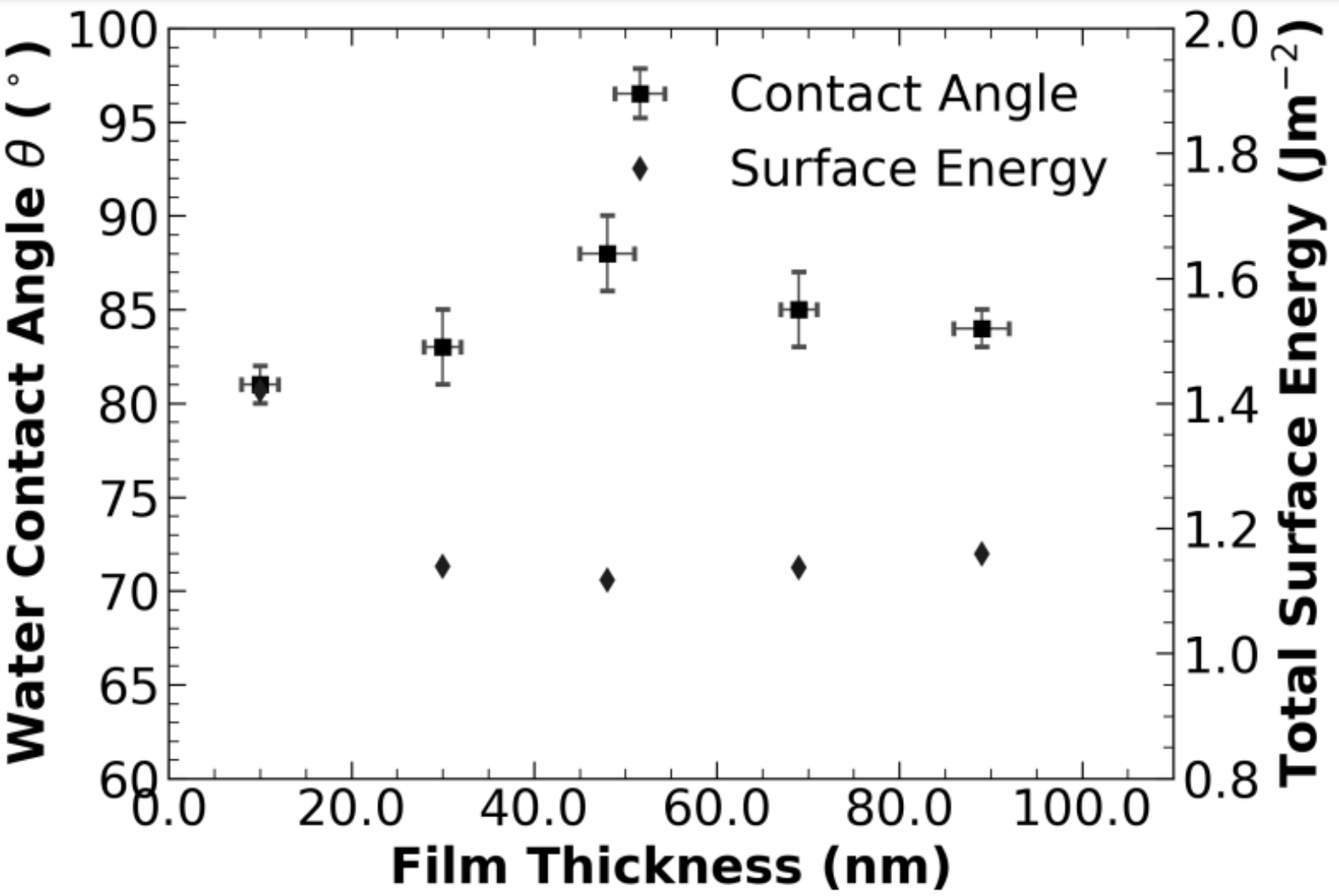

- Surface Parameter Determination: Based on variations in the shape of the liquid drop with respect to predefined thin film thickness

- Optimization of Thin Film Thickness: Identifying an optimal thickness range to enhance hydrophobicity

- Vacuum Deposition: Involves depositing the thin film in a vacuum environment with controlled process parameters

- Surface Energy and Wettability: Determination of surface parameters like surface energy and wettability before thin film fabrication

- Pre-Fabrication Analysis: Allows for the prediction of surface parameters before the thin film is deposited, saving time and reducing costs

- Enhanced Control: Provides better control over surface wettability and hydrophobicity through precise thickness optimization

- Complexity Reduction: Simplifies the process of estimating surface stress and energy compared to traditional methods

- System Components: Includes a processor, memory, and modules for performing shape analysis and determining surface parameters

- Liquid Drop Analysis: Utilizes a liquid drop (e.g., deionized water) to analyze changes in shape with respect to the substrate surface

The Technology contributes to advancements in material science and surface engineering.

- Nanocoatings: Improved encapsulation and protection for various applications

- Surface Science Research: Investigating and controlling surface interactions in various materials

Geography of IP

Type of IP

201821032983

428535