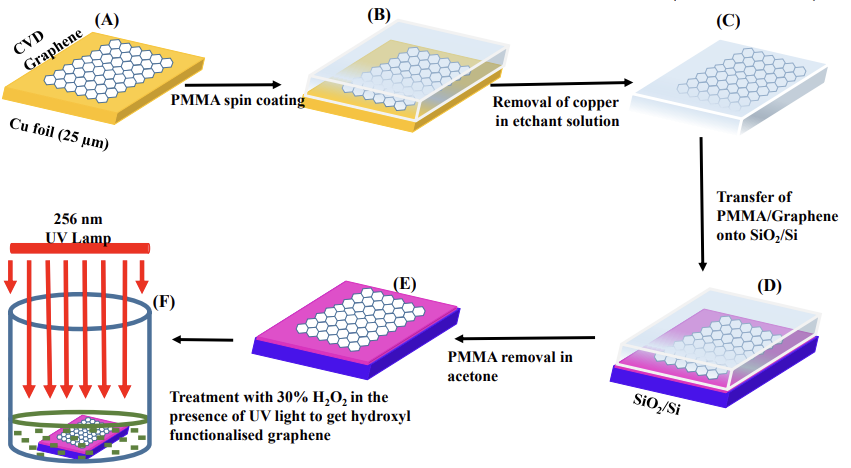

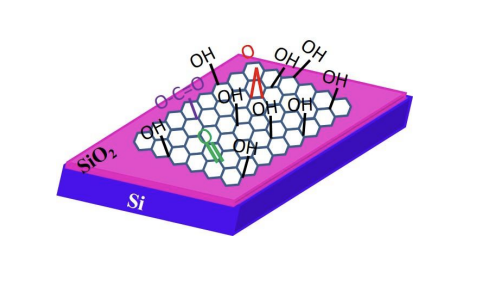

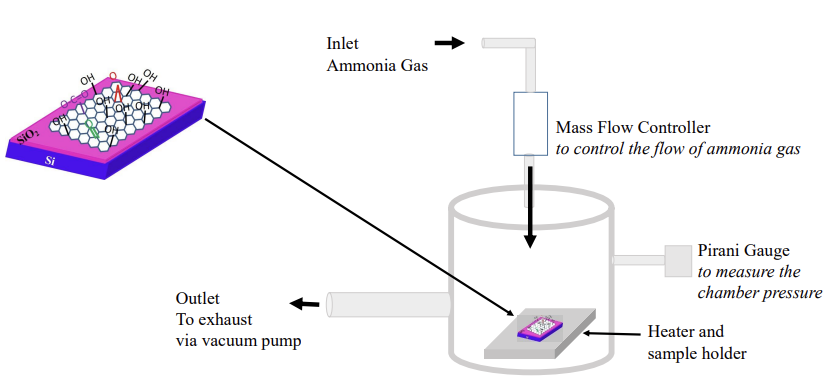

This invention presents a method to enhance Chemical Vapor Deposition (CVD) graphene by modifying its properties. Initially, the graphene is treated with hydrogen peroxide and UV light to introduce hydroxyl groups, followed by annealing in ammonia to incorporate nitrogen and induce magnetization. This approach addresses graphene’s inherent non-magnetic nature, thereby broadening its potential applications, particularly in spintronics and biomedical devices. The process is validated through spectroscopy and microscopy techniques to confirm successful functionalization and magnetization. By enabling graphene to exhibit magnetic properties, this innovation paves the way for advancements in semiconductor technology and biomedical applications, promising faster electronics and improved medical diagnostics and therapies.

CVD graphene is inherently non-magnetic, limiting its applications in fields like spintronics and biomedical devices. Current methods lack the ability to introduce magnetization into large-area CVD graphene, crucial for advancing technologies requiring magnetic properties. This limitation restricts the potential for developing faster electronics and innovative medical tools that could benefit from graphene's unique characteristics if magnetization could be effectively introduced.

- Nitrogen doping: By introducing nitrogen doping, magnetization can be imparted to CVD graphene, expanding its potential applications in spintronics and magnetic field-guided biomedical devices.

- Enhanced functionality: The ability to functionalize CVD graphene with magnetization enhances its utility in diverse technological fields where magnetic properties are essential, such as spintronic devices and magnetic sensors.

- Large area synthesis: Chemical Vapor Deposition (CVD) enables the scalable production of single-layer graphene over large areas, crucial for semiconductor devices, sensors, and other high-tech applications.

- Versatile deposition: CVD graphene can be deposited on flexible and rigid substrates alike, providing versatility in material selection for various device requirements.

- Cost-effective process: The nitrogen doping and magnetization process occurs at room temperature and uses widely used low-cost chemicals ensuring a cost-effective manufacturing approach suitable for industrial applications.

- Improved performance: Through nitrogen doping, graphene's electrical and magnetic characteristics are enhanced, offering improved performance while maintaining the material's inherent structural integrity.

NA

4

This innovation facilitates advancements in spintronics and magnetic sensing technologies. It expands opportunities for high-speed electronic devices and semiconductor technology and enhances capabilities for biomedical applications like magnetic field-guided drug delivery systems.

This technology supports innovation in material science for future technological needs and promotes sustainable technology development through efficient use of resources.

- Semiconductor devices

- Spintronics

- Biomedical devices

- Magnetic field sensing

- Nano-drug delivery

- Graphene-based sensors

Geography of IP

Type of IP

202021046163

427710