In a reactive chromatography (RC) process, the reaction and separation of products occur simultaneously within a single unit. This invention describes a method for synthesizing ketals and acetals using reactive chromatography which has the benefit of increased conversion. The process involves reacting an alkanol with a carbonyl compound in the presence of a catalyst. A key feature of this process is the introduction of an additional supplementary solvent selected from an organic non polar solvent system at a reaction temperature between -25°C and 25°C and under pressure ranging from 1 atm to 10 atm.

Certain ketalization reactions are highly exothermic and significantly hindered by equilibrium limitations. The RC process aids in driving the reaction forward by separating the product from the reaction zone as the reaction progresses but it does not significantly enhance reaction conversion using the conventional method.

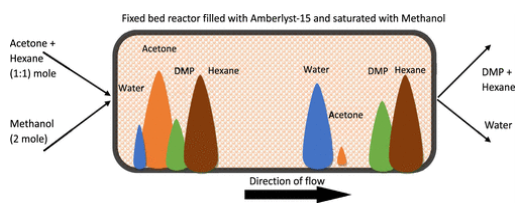

- DMP synthesis from methanol and acetone would give <10% conversion at -25 to 25°C and a mole ratio of 2:1 in a conventional reactor due to strong equilibrium limitation. Proper choice of solvent in RC increases the conversion significantly.

- Simultaneous separation of water and complete conversion of one of the reactants reduces the problem of down stream processing.

- Reaction is conducted in a stainless-steel reactor equipped with a jacket for coolant circulation.

- Amberlyst 15, a cationic resin as a strong acidic catalyst, is filled in the reactor as it has more affinity for water & less affinity for ketal & ketone.

- Water as a coolant is used when the required reaction temperature is above 0°C, and a water-ethylene glycol mixture is used for a sub-zero reaction temperature.

- Residence time varied from 30 minutes to 80 minutes depending upon bed size and flow rate of the feed mixture.

- The steady state (SS) conversion in case of ketalization of methanol and acetone was found to be between 15 to 17 % at column outlet.

This invention is at the stage of early prototype development and/or validation in relevant environment.

3

Ketals are often used as solvents or raw materials for important fine chemical intermediates. For example, DMP is used as a dehydrating agent, intermediate for fragrances, agrochemical, insecticides, fungicides and in pharmaceutical intermediate. It is also used as an intermediate for statins production, which is used in drugs to reduce the high risk of cardiovascular diseases. Using the RC process and choosing a perfect solvent, one can get higher product yield. Simulated moving bed reactor (SMBR) will improve its commercial applicability, and make it easier to scale up depending upon the industrial demands.

- Pharmaceutical

- Agrochemical

Geography of IP

Type of IP

201921035595

396666