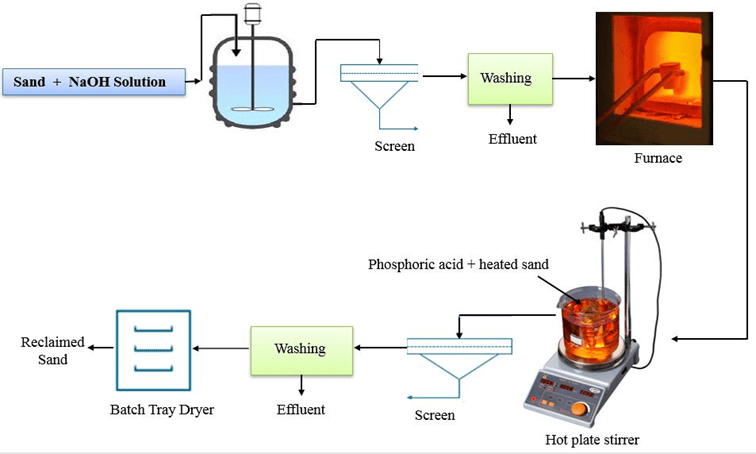

In India, millions of tons of waste foundry sand (WFS) is dumped annually without undergoing any scientific disposal treatment. Due to the lack of a viable techno-commercial solution for treating WFS, its disposal continues to be a significant challenge. Thus, a process for reclaiming waste foundry sand which involves reacting the waste foundry sand with industrial effluent that has a predetermined acid concentration has been proposed. This process also includes a method for treating industrial effluent using waste foundry sand.

Chemical industries generate significant waste in the form of effluents. If these wastes are not properly recycled or treated before disposal, they can severely impact the environment through air, water, and soil pollution. Both large and small-scale industries have often neglected the proper treatment of hazardous wastes, leading to ongoing environmental degradation. Effective treatment, tailored to the severity of the effluent, is essential but typically capital-intensive.

- This innovative technology produces sand comparable to fresh sand, making it ideal for core making.

- Usage of industrial effluent to reclaim waste foundry sand provides the added benefit of significantly reducing the total organic carbon (TOC) and chemical oxygen demand (COD) in the effluent, thus making its disposal much easier.

- It establishes zero-waste foundries by making them partially or fully independent of sand mining.

- It preserves the ecosystem by reducing sand mining and minimizes the environmental footprint by avoiding waste sand disposal.

N.A.

The invention is currently at the stage of having a developed Proof of Concept.

3

Treatment of effluent using waste foundry sand helps to safely dispose off hazardous waste thus decreasing various types of pollution of the environment like air, water and soil pollution.

This sand reclamation technique holds tremendous potential for commercialization. It offers a holistic approach to establishing zero-waste foundries, addressing their needs by making them partially or fully independent of sand mining. Additionally, it helps preserve the ecosystem by eliminating the need for sand mining and reducing the environmental footprint associated with waste sand disposal.

The proposed chemical reclamation process transforms waste foundry sand (WFS) into a material suitable for core production, significantly enhancing its value.

Geography of IP

Type of IP

202021020228

505167