The present invention relates to a microfluidic device designed for the generation of droplets, emulsions, particles, single and multi-core microcapsules, microbubbles, single microfibers, core-shell microfibers, and nanoparticles. This device comprises glass capillaries and a polydimethylsiloxane (PDMS) slab, with the PDMS slab incorporating a T-junction. It holds significant commercialization potential across the biomedical, pharmaceutical, chemical, and food industries. This hybrid microfluidic device features a versatile design that accommodates multiple applications. Additionally, it can be constructed using various materials such as plastics, polymers, and PMMA. The design can also be adapted for printing on 2D microfluidic chips, offering further versatility and potential uses.

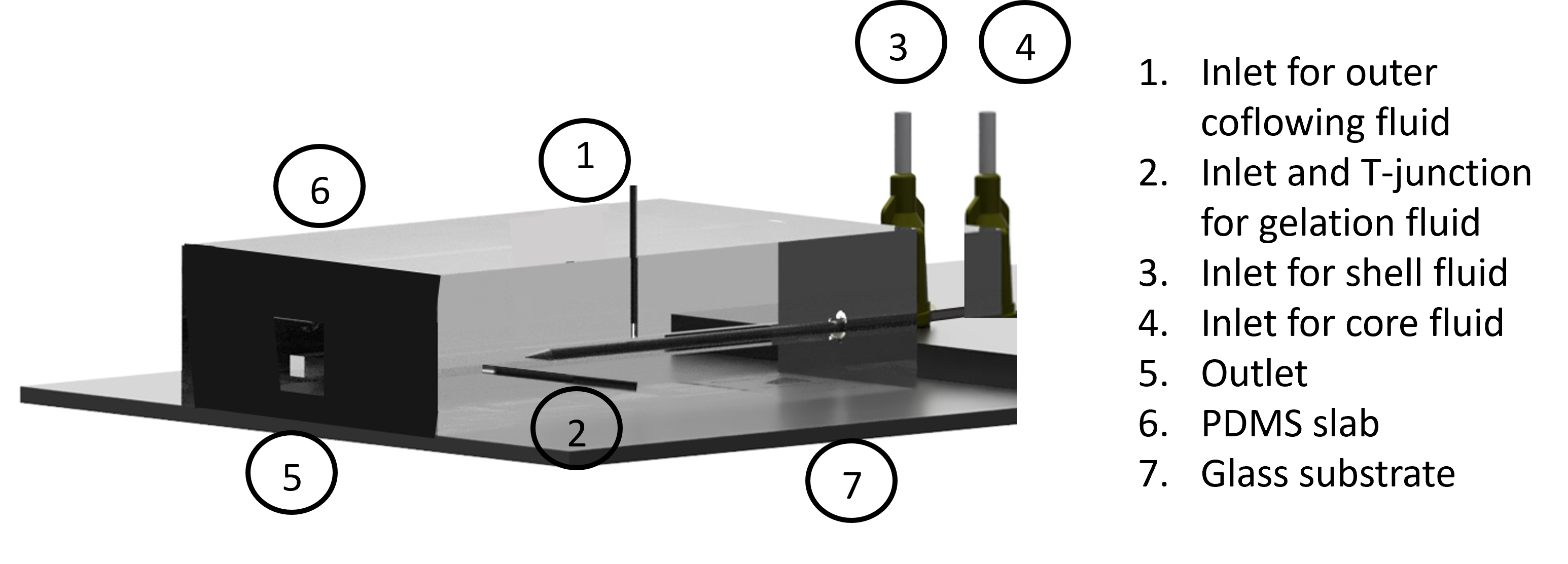

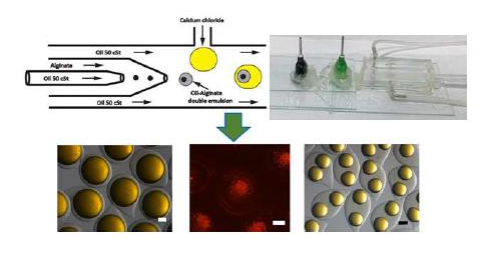

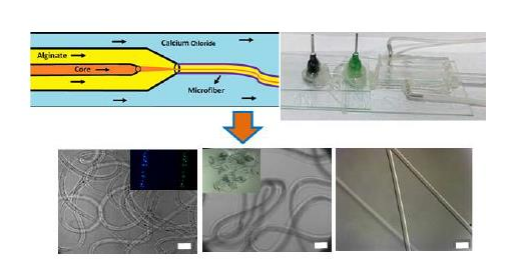

Figure (1) 3D drawing of microfluidic device for core-shell microcapsule generation; (2) Schematic of the microfluidic device showing droplet generation from co-flow (for core-shell formation) (oilalginate double emulsion) and from T-junction (for sheath formation) (aqueous calcium chloride) followed by merging for on-chip polymerization and generation of oil core-alginate shell microcapsules; (3) Schematic of the microfluidic device showing core-shell microfiber generation from coflow and T-junction (aqueous calcium chloride) followed by on-chip polymerization and generation of core-shell microfiber.

A major limitation of the designs of microfluidic chips is the need for selective customization for each specific application, which hinders the advancement of research and technology. Additionally, the existing designs face numerous issues, such as leaking, blocking, clogging, swelling, improper cleaning, choking, and poor bonding, and are based on processes that are not suitable and pose difficulties for biological entities.

- This innovative device can be used for:

- the generation of droplets, emulsions, particles, etc. without any modification in design;

- the generation of microcarriers in a very broad range (10 to 1500 microns);

- the encapsulation of cells, drugs, and nanoparticles in the polymeric matrix; and

- carrying chemical reactions at the microscale.

- Arrangement of extra channels and any modification in the design can be done easily.

- The device is compatible with high electric field inside the microchannel as it can withstand a high voltage supply.

- It does not need any sophisticated equipment and can be produced at economical cost.

- The device has a long lifespan and is reusable provided it is cleaned thoroughly between two applications.

- Glass capillary part houses co-axial flow

- PDMS slab is of width 250 mm, length 450 mm and a main channel of size 1.4 mm

- PDMS slab is prepared from a mixture of PDMA and curing agent in ratio 10:1

- Channel is of any shape, particularly of square shape

- Channel inside the PDMS slab is prepared by pouring a mixture of PDMS and curing agent on a long 1.4 mm side square glass capillary supported by a teflon frame

- For formation of double emulsion droplet, one end of the main channel is inserted with coaxially aligned two cylindrical capillaries pulled to tip diameters of 110 microns and 80 microns providing inlets for shell and inner core respectively

- For formation of single emulsion droplet, the main end of the channel is inserted with single cylindrical capillary of tip diameter 100 microns

Proof of concept has been developed.

3

The invention helps to eradicate the barriers to advancement of research and technology. The invention has applications in major areas such as drug delivery, therapeutic applications, tissue engineering, which can be used to battle diseases and promote better health of the public.

The hybrid microfluidic device is highly useful for producing droplets, emulsions, particles, single and multi-core microcapsules, microbubbles, single and core-shell microfibers, and nanoparticles. These microstructures have numerous applications in the following domains:

- Healthcare, Biomedical & Pharmaceutical industry - single-cell analysis, antibody production, cell encapsulation, tissue engineering, antimicrobial activity, drug delivery, drug assays, therapeutic applications

- Chemical industry - conduct chemical reactions in a microreactor

- Food industry

Geography of IP

Type of IP

202021029263

456399