Carbon fiber reinforced epoxy composites are renowned for their exceptional performance due to their high strength-to-weight ratio. High modulus carbon fibers serve as the primary reinforcement in CFRPs (carbon fiber reinforced plastics), typically sized with polymers for handling and weaving purposes. However, surface flaws on the fibers can cause premature failure under tensile loading. Removing the sizing agent and oxidizing the carbon fibers are crucial steps to eliminate surface flaws and impurities.

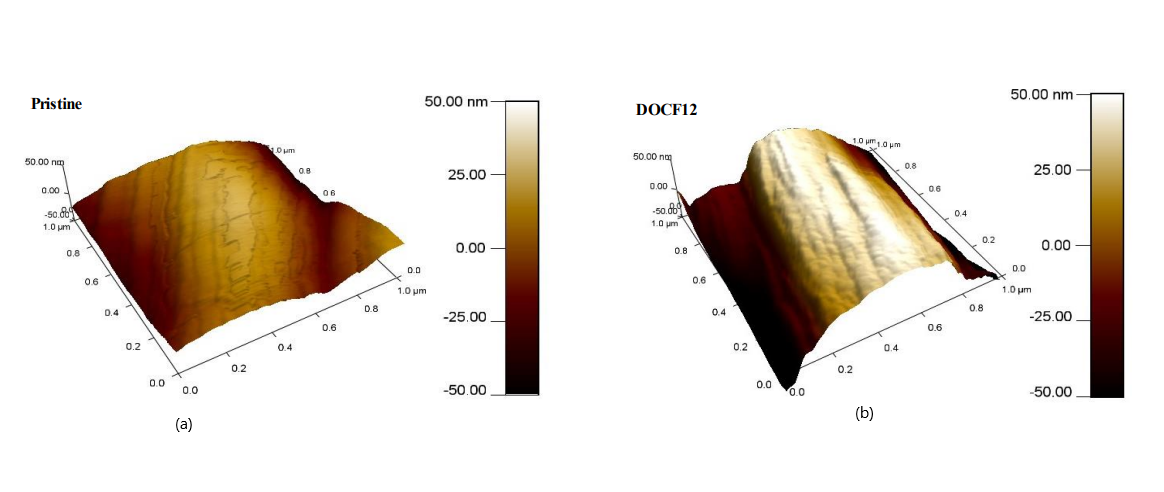

In this invention, carbon fibers were desized and subsequently oxidized with optimized treatment times. This process resulted in a significant improvement in the tensile strength of the treated fibers compared to untreated ones. The treated carbon fibers were characterized using SEM, FTIR, and AFM to examine micrographs, functional groups, and surface roughness, respectively. These treated carbon fibers are highly suitable for further manufacturing of CFRPs.

The smooth, chemically inert, and non-polar surface of carbon fibers results in poor fiber/matrix interfacial bonding, leading to weaker composites that fail under tensile loading. The removal of sizing agent and the oxidation treatment of the carbon fibers is essential to remove the surface flaws/impurities from the carbon fibers.

- More contact points enhance mechanical interlocking between fibers and/or matrix.

- Optimized desizing and oxidation treatment method and conditions achieve maximum enhancement in the performance of carbon fibers.

- It introduces functional groups on the carbon fiber surface capable of enhancing interfacial adhesion.

- It provides carbon fibers with improved tensile strength and tensile modulus.

- It shows improved failure strain compared to pristine carbon fiber tows.

First, the carbon fiber cloth was cut into 150 mm x 150 mm pieces and placed in a 5-liter glass reaction kettle. One liter of acetone was then added to the kettle, which was heated on a hot plate. The carbon fibers were desized by refluxing at 70℃ for 48 hours. A condenser mounted on top of the reaction kettle was used to condense the evaporated acetone during the reflux process. After desizing, the carbon fibers were thoroughly washed with deionized water until the pH value reached 7. The fibers were then dried at room temperature for 12 hours, followed by an additional 12 hours at 60℃ in a vacuum oven. Finally, the desized carbon fibers underwent oxidation to functionalize their surfaces.

The invention has a proof of system and is ready for deployment. The treated carbon fibers were characterized under scanning electron microscope (SEM), atomic force microscope (AFM) and fourier-transform infrared spectroscopy (FTIR) for micrographs, surface roughness and presence of functional groups respectively and were shown to have improved tensile strength.

9

The treated carbon fibers can be used in manufacturing technologies for aircraft, vehicles, high-performance sports gear, and infrastructure projects.

The invention has significant applications in industries that rely on high-performance composite materials. Carbon fiber reinforced epoxy composites are widely used in aerospace, defense, automotive, sports equipment, marine, energy, and civil engineering sectors due to their superior strength-to-weight ratio and durability.

Geography of IP

Type of IP

202221005350

409126