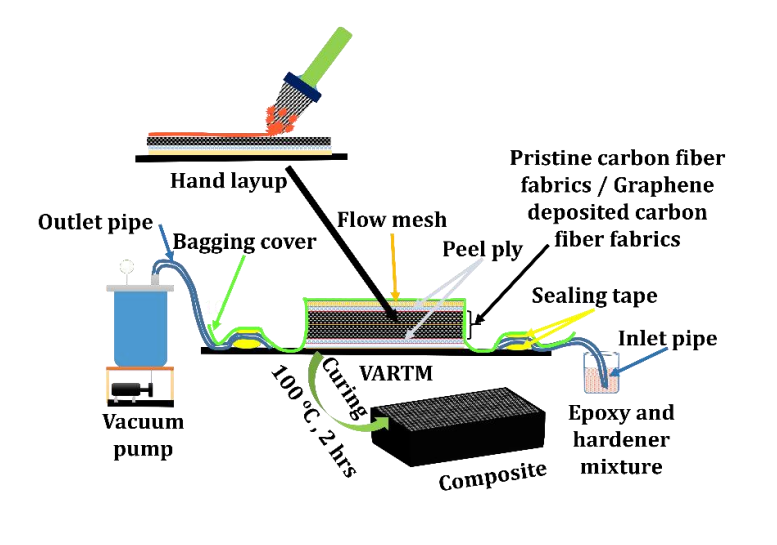

The invention is related to carbon fiber reinforced polymer (CFRP) composites. Specifically, it describes a method for fabricating carbon fiber fabrics with enhanced mechanical properties. The method combines partial hand layup (HL) with vacuum-assisted resin transfer molding (VARTM) for the fabrication of CFRP composites. The resulting CFRP composites exhibit improved tensile strength, tensile modulus, flexural strength, flexural modulus, and increased strain at maximum tensile and flexural stress.

Carbon Fiber Reinforced Polymers (CFRPs) often face issues like weak interfaces and insufficient strength. Traditional fabrication methods, such as autoclave and additive manufacturing, are expensive, labor-intensive, and time-consuming, requiring extensive post-processing and are unsuitable for industrial application. Additionally, composites manufactured using Vacuum Assisted Resin Transfer Molding (VARTM) suffer from reduced strength, making them more prone to interface failure under mechanical loading.

- Fabricates high strength CFRPs with enhanced mechanical properties

- Enhances the tensile and flexural properties of CFRPs

- Improves interfacial strength of CFRPs

- Performs a combination of hand layup (HL) method followed by VARTM

- Enables proper resin wetting of the carbon fiber fabrics and reduces void formation

The process involves preparation of a resin mixture with atleast one epoxy resin and a hardener. This partial resin mixture is then applied to carbon fiber fabrics by stacking it layer-by-layer to obtain the CFRP composite. This composite is then subjected to a combination of VARTM and HL method to improve its properties. The flexural strength of the composite has been shown to be 95% higher than the composite using just the VARTM method. There were significant improvements in other properties, like 8% boost in tensile strength, 2.3% increase in tensile modulus, and so on.

The invention is at TRL 9 and has a proof of System/process ready for deployment.

9

The invention utilizes CFRPs which are very useful for various industries such as Automotive industry, Aerospace industry, Sports equipment, defense industry, hydrogen storage, space, prosthetics.

Geography of IP

Type of IP

202321066950

542964