Calcium carbide residue (CCR) is a waste by-product of acetylene gas manufacturing industry. Because of its zero recovery value, the present Indian practice is to dump it in open land or landfills. This not only adversely impacts the volume of the landfill, but also reduces the biodegradation process of many other wastes because of its high alkali content. Hence to support the environment, it is necessity to develop means to reuse this industrial waste. This is the background of the study.

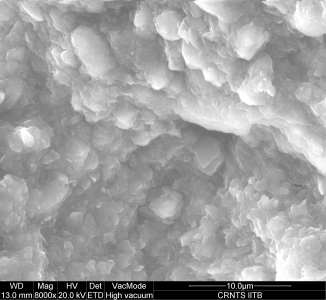

CCR has over 80% of CaO and if mixed with soils which have the right amount of SiO2 , Al 2 O 2 and Fe 2 O 3 forms pozzolanic cement to naturally bond and improve the engineering properties of the soil. Black cotton soil (montmorillonite clay) has been identified as the right candidate with the right amount of reactive silica with which CCR can blend. These soils are spread over parts of Maharashtra, Madhya Pradesh, Gujarat, Andhra Pradesh, Karnataka, Tamil Nadu and Uttar Pradesh. On its own, this soil is poor for construction, swells in rainy season and shrinks in dry season. CCR has shown the potential to stabilise this soil and replace other traditional but expensive additive materials. CCR altered the clay mineralogy and its morphology which resulted in a complete and sudden change in the soil’s compressibility and strength.

Prof. A Juneja