Our research work focuses on indigenous development of low-cost bioresorbable medical bone screw for bone-soft tissue Fixation applications. There is a huge demand for orthopedic devices in India and worldwide. It is estimated that more than 100 million screws are used for bone or soft-tissue fixations per year globally.

To demonstrate proof-of-concept of bioresorbable bone screw prototype composed of novel composite biomaterial with advanced functionality:

■ Development of novel biomaterial composite of n-MgO/Silk/PCL melt mixed in different ratio for tunable properties and its in-vitro physicochemical, mechanical, biological characterisation

■ Development of injection molding molds according to reference screw design using machine tool workshop facility

■ Fabrication of bone screw prototype using micro compounding and injection molding and its in vitro, ex vivo biological and mechanical evaluation

■ In vivo evaluation of as-developed composite bone screw for biocompatibility and toxicity by subcutaneous implantation in SD rats

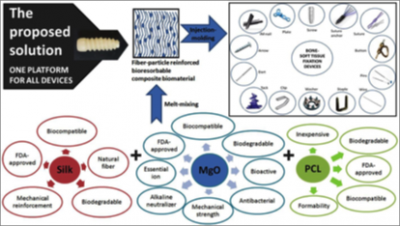

Novel composite biomaterial (MgO - silk fiber reinforced in Polycaprolactone) was developed achieving advanced functionalities with variable filler concentration:

a. Tunable mechanical properties (tensile strength = 15-30 MPa and modulus = 0.2-1.2 GPa) matching that of cancellous bone, tendon and ligaments;

b. Enhanced in-vitro biological properties (biodegradation, biomineralisation and biocompatibility);

c. Ex vivo hemocompatibility studies with human blood revealed no interference with normal blood cell viability, count, coagulation process, etc.;

d. In vivo biosafety studies showed minimal inflammatory response by 8 weeks in tissue surrounding implant with no adverse effect on vital organ functions.

Presently, our research team is working on ex-vivo biomechanical studies (pullout test):

1. In-house injection molding capability was developed in terms of custom- manufactured molds with pocket-pin assembly to fabricate bone screw of desired shape and size

2. Proof-of-concept was demonstrated by fabricating PCL and MgO-silk-PCL bone screws (cannulated and non-cannulated) fitting regular hexagonal Allen keys of different head diameters (3 mm and 4 mm).

Prof. Rohit Srivastav