Electronic waste comprising of predominantly consumer electronic goods is increasing at an alarming rate since the past decade. Treating this electronic waste to recover as many valuables as possible is one way to tackle this menace without changing any of the materials or manufacturing processes. An alternative however is to develop technologies that will utilise only environmentally friendly and sustainable materials for the next generation of consumer electronic devices. This requires a change in the approach to materials selection and design and many nations are exploring these options for future electronic devices.

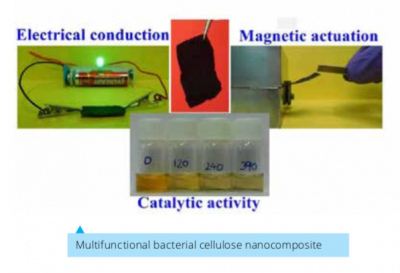

Cellulose is a unique natural biopolymer which is abundant, environmentally friendly, biocompatible and sustainable. Functionalising this material for different applications, keeping in mind the condition that it has to be environmentally friendly and sustainable is a challenge. In our approach to materials selection and design, cellulose produced by bacteria which is the more superior form compared to plant cellulose, has been functionalised to exhibit magnetic actuation, electrical conduction and catalytic activity with just one additive. A unique synthesis technique called ‘Inverse Chemical Reduction’ has been developed to introduce this single additive into bacterial cellulose. The resulting hydrogels as well as aerogels were found to exhibit the three functionalities – magnetic actuation, electrical conduction and catalytic activity for pollutant reduction. This technique is extremely simple, scalable and uses inexpensive additive pre-cursors.

Prof. S Vitta