Continuous flow process provides a potential alternative to batch synthesis because of its inherent advantages such as efficient heat exchange, high batch to batch reproducibility, fast mixing, high throughput, safety and the ability to do multi-step telescoping synthesis. Due to these advantages, these processes have been referred to as the most promising ‘Green Technology’. Continuous flow processes also provide an ‘On-Demand’ synthesis with complete control over reproducibility, size, shape and these parameters can be achieved at various scales (lab synthesis to pilot to bulk production) with excellent reproducibility. In fact, continuous flow processes are projected to be the ‘CHEMICAL FACTORIES’ of tomorrow. It enables one to carry out protection or deprotection free chemistry as well as to carry out extremely fast reactions wherein the reactive intermediates can be trapped before they undergo conventional organic reactions. This has forced organic chemists to relearn

their retro-synthetic strategies (for the most efficient design of a synthetic route. This has profound impact on) the development of shorter and more efficient synthetic routes for important targets and Application program interfaces APIs.

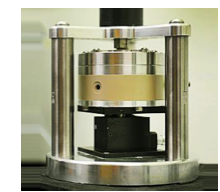

In this direction, we have setup a first of its kind, state of the art laboratory equipped with all the tools which includes pumps (lab sale to production scale including pumping for corrosive and/or air sensitive reagents), reactors (from Micro to macro to production scale reactors) PAT tools (inline FTIR, UV-Vis and FT NMR). We provide regular training to generate skilled human resources in this important area of future technology for production of chemicals in an economically and environmentally viable mode.

Prof. A Kumar