With growth and advancement in science and technology, electronics and electrical systems continue to be placed in denser packaging and smaller enclosures. All electronic and electrical devices heat up while working. Due to compact packaging, their temperature rises as sufficient heat cannot be dissipated naturally. For high efficiency and reliable performance of electronic equipment, the rising of temperature above room temperature needs to be controlled. High rise in temperature can be detrimental for the working of the devices. For ensuring proper working of the electrical equipment or devices, the heat generated must be effectively removed.

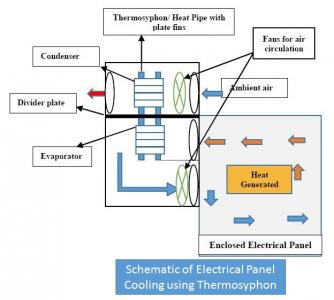

Thermosyphon is a device which carries a lot of heat out of the system with no external pumping power. It can carry large amount of heat to long distances with extremely small temperature drops. Thermosyphons are exceptionally flexible and have simple construction with no moving parts so that they can be easily incorporated into any electrical systems for easy removal of excess heat generated. They contain a working fluid which boils at the evaporator section absorbing the excess heat from the electrical panel and then the vapors formed travel to condenser section due to buoyancy. At the condenser section, the vapours reject heat to the surroundings and get condensed back to liquid which flows back to the evaporator due to gravity, thus completing the cycle. These thermosyphons could be used for cooling of various electrical devices, electrical panels, circuits, etc. to ensure optimum working temperature. At the Refrigeration and Cryogenics Laboratory in IIT Bombay, a thermosyphon unit has been developed using acetone as a working fluid which is able to remove excess heat and maintain a temperature difference of about 10°C above ambient inside an enclosure which generates a heat load of 300 W while keeping the electronic/electrical equipment inside the enclosure protected from harsh environment i.e., dirt and debris, corrosive vapors and water.

Prof. Milind Atrey