The major obstacles in utilizing crude tire pyrolysis oil in combustion equipment are the high content of sulphur and nitrogen, high polyaromatic fractions, and inferior fuel properties resulting in low flash point, poor storage stability, high acidity, and offensive odor.

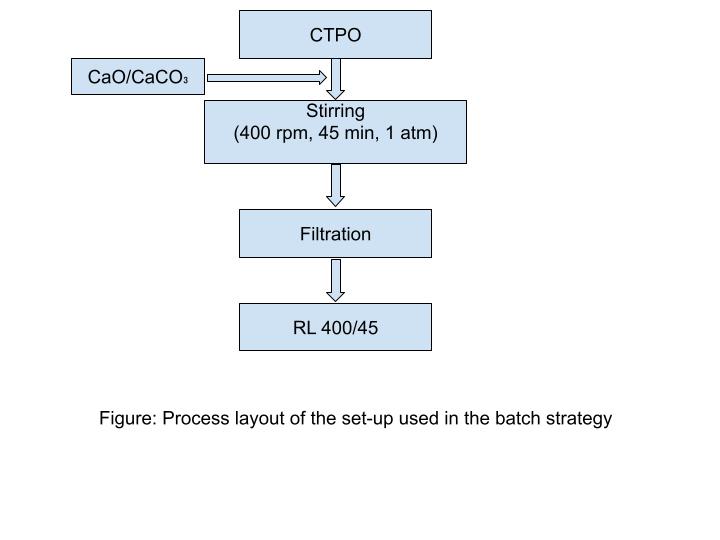

Annually, around 1.5 million tonnes of waste tires are discarded worldwide, contributing significantly to environmental pollution known as "black pollution." This invention presents a novel and scalable strategy for upgrading crude tire pyrolysis oil (CTPO) using calcined eggshells as an adsorbent. The method effectively removes sulphur and polyaromatic hydrocarbons (PAH) from CTPO, improving its quality for use as a fuel in furnaces and engines.

- Utilization of waste eggshell-based adsorbent, for the selective adsorption of sulphur and PAH from CTPO

- Less energy and capital-intensive

- Refined oil properties closely match those of furnace fuels, ensuring compatibility with existing fuel standards

- Enhanced sulphur removal efficiency compared to other adsorbents No need for recycling the adsorbent, reducing operational complexity

- Scalability for small and large-scale polymer-based pyrolysis units

Yet to be developed

The technology has been tested at a laboratory scale, demonstrating significant improvements in the quality of CTPO, including better fuel properties and reduced odor.

3

This invention addresses the environmental hazards of waste tires by transforming them into valuable fuel, reducing pollution, and promoting sustainable waste management practices.

Tire recycling, waste management, fuel production, and industries that use CTPO as a fuel source.

Fuel production for gas turbines, steam boilers, marine engines, furnaces, and internal combustion engines.

202321049485

537628